CURVEYOR

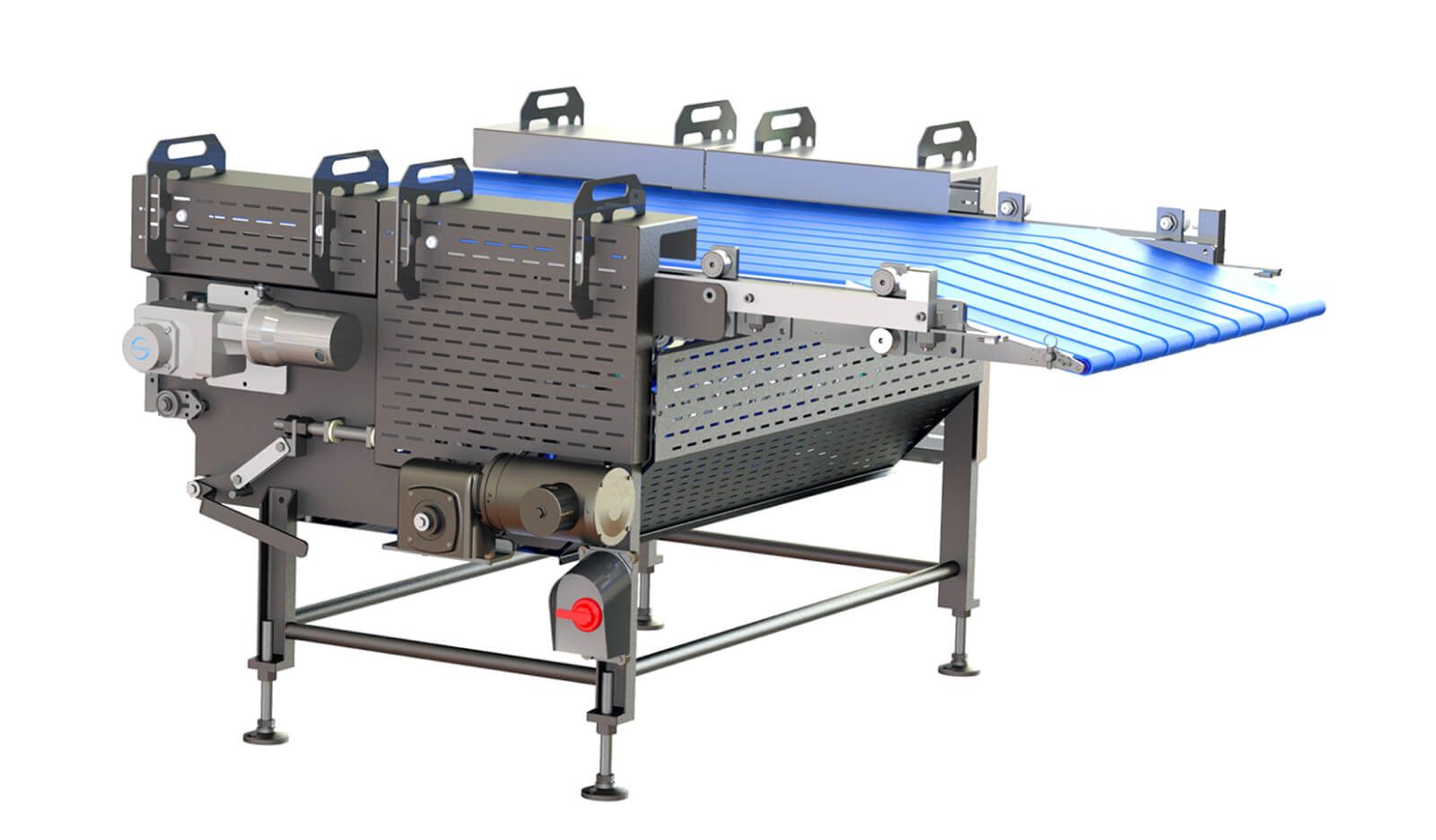

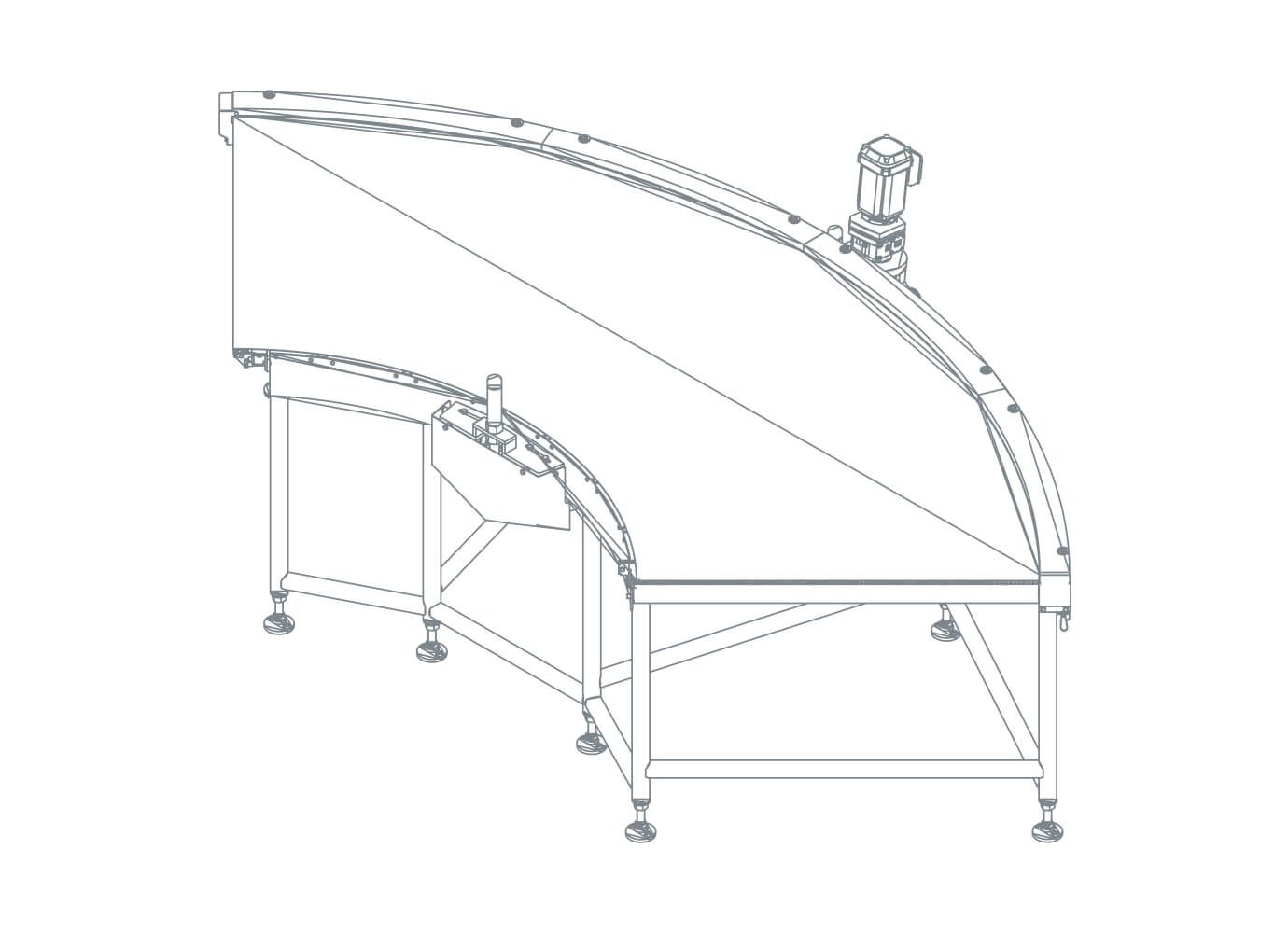

FIT TIGHT TURNS AND TRANSFERS

Seamlessly move your product around turns, corners, and other equipment then gently transfer it to the next step.

WHY CURVEYOR?

FLEXIBLE CONFIGURATIONS

DAMAGE-FREE CONVEYING

SANITARY & MAINTENANCE FRIENDLY

Product Features

-

Available with 30-180 degree turn radius

-

Bi-directional product flow

-

Center-driven powered belt turns

-

Tight transfer 5/8” or 7/8” rolling nosebars for smooth, damage-free transfers

-

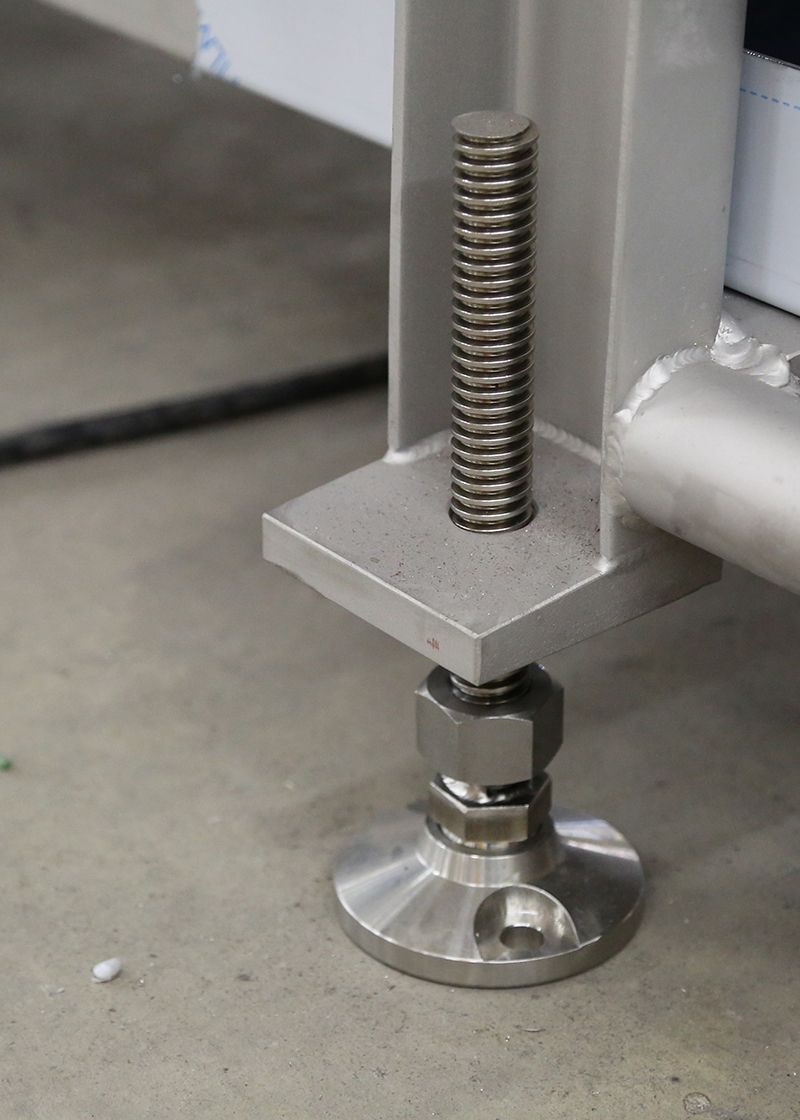

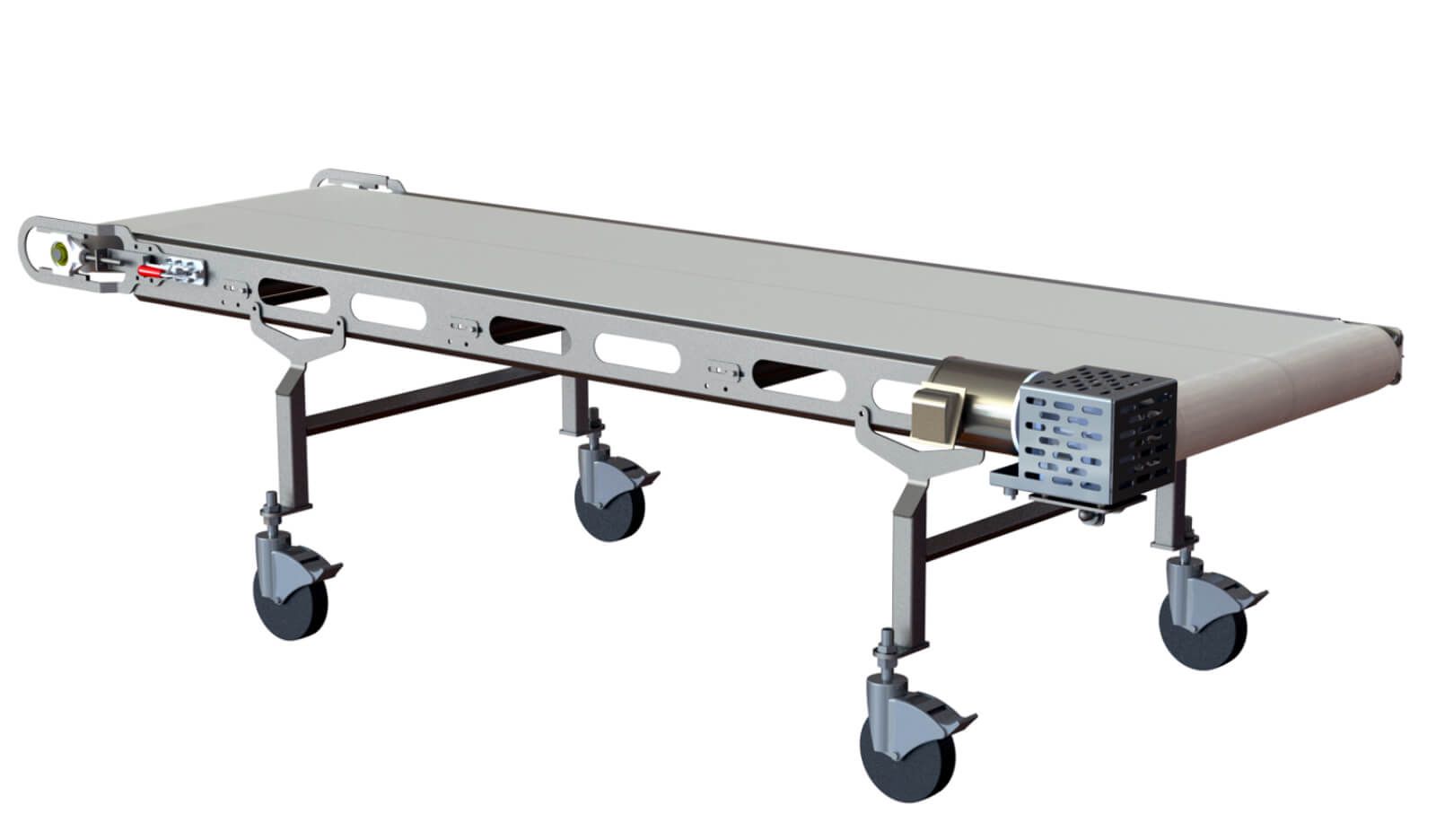

Food-grade sanitary design with open frame and simple belt changes in 30 minutes

SPECS

Natural belt tracking

Turn Radius

30-180 degrees

Max Speed

200 FPM

Width

14-84” (355-2134 mm) effective

Height

dependent on width, as low as 30” TOB

Motor/Drive

SEW gearmotor, Stober gearbox/Baldor motor

Electrical

230/460 volt standard; 575 volt or 110v optional

Options

- Dry clean, wash down, and ready to eat (RTE) sanitation levels

- Belts: 2-ply, finger spliced endless, white or blue, high-temp

- Left or right-hand orientation

- Ceiling support frame

- Nose rollers: 5/8” or 7/8” tight transfer, or 2.25” segmented

- Belt scraper (tool-less removal)

Service & Parts

Our expert customer and field service teams work hand-in-hand with you to find the solutions you need, quickly and efficiently.

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to integrate the line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

COMMON FOOD INDUSTRIES

Whether your product is sticky, dusty, wrapped or not, the Curveyor can convey it throughout your processing line damage-free. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

REQUEST A CONFIGURATION

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions