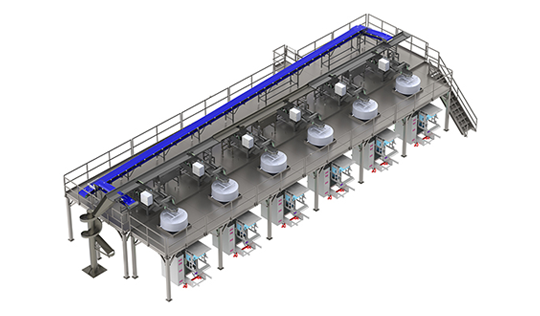

FORKLIFT DUMPER

AUTOMATIC & SAFE ELEVATED TOTE AND CRATE UNLOADING

Efficient, high production handling for your bulk product containers.

WHY THE FORKLIFT DUMPER?

FLEXIBLE OPTIONS

OPTIMAL PRODUCT HANDLING

SAFE OPERATION

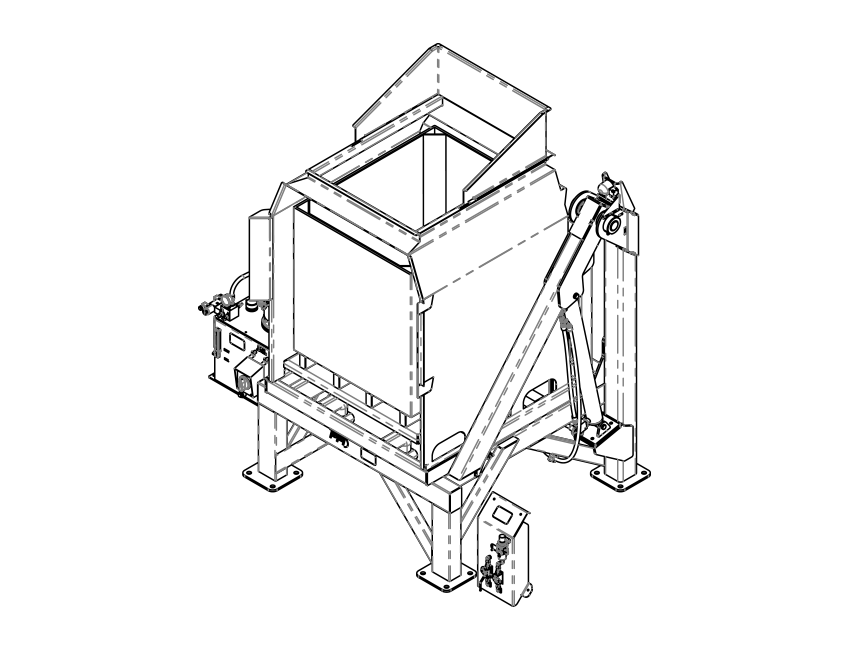

Product Features

-

Single stage with 60-degree discharge angle

-

Handle up to 1,800 pounds totes on standard model or 3,000 on the 5:1 safety factor design

-

Optional positive seal system lifts and seals the box before tilt – eliminating the possibility of debris

-

Sanitary open-frame, tubular design with RTE level available

Specs

Hydraulic cylinders

Single stage tilt

60-degree discharge angle

Dumping Height

66” (1676 mm) and up

Weight Capacity

up to 3,000 lbs. standard

Options

Additional equipment options to customize the Eleveyor precisely to your application.

- Stainless steel or mild steel construction

- Wash down or RTE sanitation levels

- Positive seal system

- 3:1 or 5:1 safety factor

- Mounted or separate controls

Service & Parts

Our expert project managers and technical service teams work hand-in-hand with you to find the solutions you need, quickly and efficiently, so you can stay up and running.

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to integrate the line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

COMMON FOOD INDUSTRIES

Whether your bulk product is raw, dusty, wrapped or not, the Forklift Dumper can handle and unload it throughout your processing line. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

REQUEST A CONFIGURATION

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions