GENERAL CONVEYING

RELIABLE, GENTLE PRODUCT CONVEYING FROM END TO END OF YOUR PROCESSING LINE

WHY CONVEY?

FLEXIBLE CONFIGURATIONS

OPTIMAL PRODUCT INTEGRITY

INTEGRATION-READY

SANITARY DESIGN

CONVEYOR COMPARISON

-

![Sliced cheese stacked on a belt conveyor.]()

Horizontal Belt

Connect your processing line with a durable conveyor built for your exact layout with a range of belt options.

Type:

Flat-bed Belt Conveyor

Length:

application specific

Width:

application specific

Key Feature:

Available with thermoplastic, modular, or fabric reinforced belts.

-

![]()

PURmotion

Gentlest product handling, flexible operation, speed control, and safe IP69 design.

Type:

Horizontal Motion

Length:

up to 20’

Width:

up to 36”

Key Feature:

Sealed servo drive for immediate start/stop and reversing.

-

![]()

VFII

Versatile, easy-to-maintain conveyor for all of your value-added applications.

Type:

Vibratory

Length:

6-24’, dependent on width

Width:

12-72”

Key Feature:

Excited base frame reduces stress and maintenance.

Design, Testing + Installation

CURVEYOR

The Curveyor curved belt conveyor seamlessly moves your product around turns, corners, and other equipment then gently transfers it to the next step. Its available in 30-180 degree turn radius and various widths, with bi-directional flow.

FULL SYSTEM SUPPORT

Trust PFI to design and manufacture the complementary structures you need around your key processes. From stairs to platforms, we put the same craftmanship into integrating and supporting your entire line.

COMMON FOOD INDUSTRIES

Whether your product is sticky, dusty, wrapped or not, our equipment can convey it throughout your processing line. We have decades of experience in the following food industries. Don’t see your category? Contact us for your custom configuration.

FIND THE RIGHT SANITARY CONVEYING EQUIPMENT FOR YOU

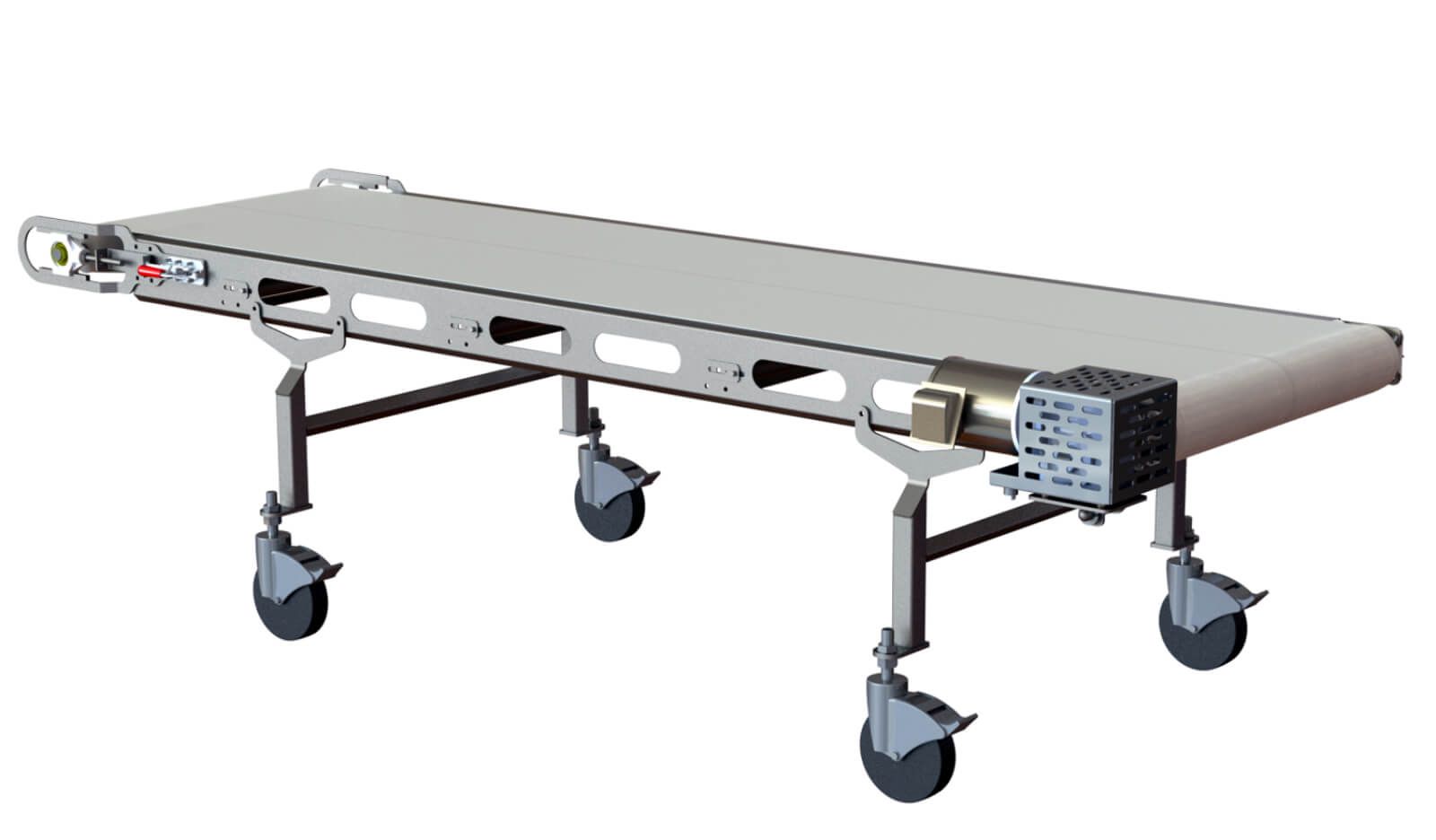

Horizontal Belt Conveyor

Connect your processing line with flat-bed conveyors built for your exact layout with a range of belt options.

Screw Conveyor

Incline raw and dry bulk food products without spillage or loss. Integrate with dumpers and more throughout your mixing, grinding, and other processes.

THE PFI DIFFERENCE

OTHER APPLICATIONS

REQUEST A CONFIGURATION

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions