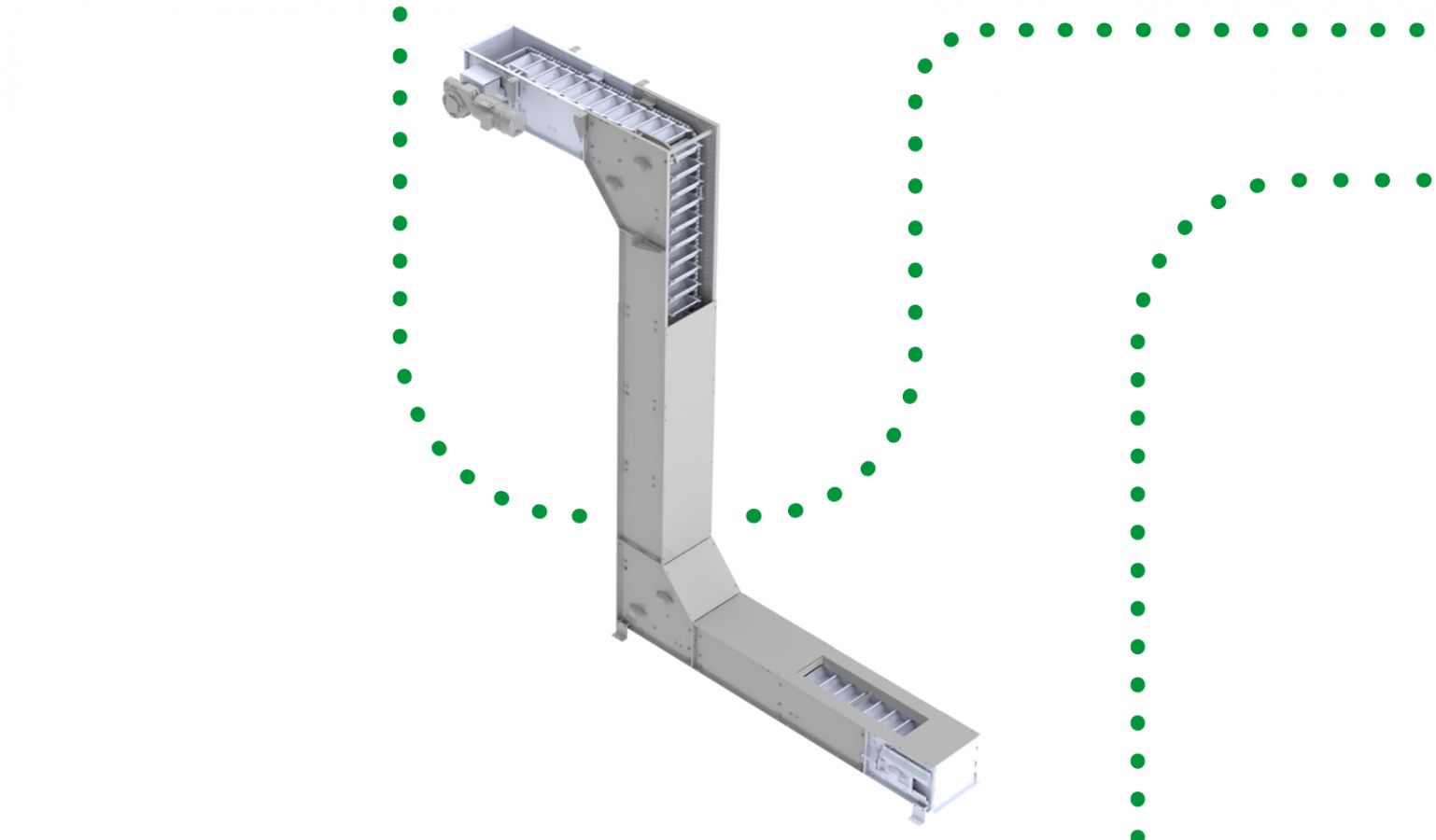

BUCKET ELEVATOR

HIGH VOLUME, VERTICAL CONVEYING

Gently elevate your raw product to the next step in your process with minimal product waste on a dependable elevator conveyor.

WHY THE BUCKET ELEVATOR?

A time-trusted, long-lasting conveying solution that vertically lifts high volumes of product to the key processes on your food processing line in a small footprint. Take your production to new heights with the Bucket Elevator.

FLEXIBLE CONFIGURATIONS

OPTIMAL PRODUCT HANDLING

TRUSTY OPERATION

Product Features

-

Horizontal, S, C or Z-shape configurations

-

Available with multiple discharges for additional layout flexibility

-

Capacity ranging from 135-3780 cubic feet per hour

-

Easy access buckets with quick, tool-less changeouts

Specs

Key details to help you decide if the Bucket Elevator is right for your operation.

Horizontal, S, C or Z-shape configurations

V-style overlapping buckets

Buckets:

Polycarbonate, polyethylene, stainless steel

Chains:

Mild steel standard, stainless and Hydro-Service optional

Flow rates:

135-3780 cubic feet per hour

Bucket Widths:

6-48” (152-1219 mm)

Height:

width and application dependent

Electrical:

460/230V 60 Hz 3Phase

Options

Additional equipment options to customize the Bucket Elevator precisely to your application.

- Open tubular or closed casing frames

- Stainless or mild steel construction

- Low, Medium, and High Capacity models

- Positive controls

- Multiple discharges

- Buckets: standard, ribbed, color, metal-detectable

- Options: CIP system, slide-out catch pans

Service & Parts

Our expert project managers and technical service teams work hand-in-hand with you to find the solutions you need, quickly and efficiently, so you can stay up and running.

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to integrate the line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

COMMON FOOD INDUSTRIES

Whether your product is raw, dusty, wrapped or not, the Bucket Elevator can lift it throughout your processing line. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

SANITARY DESIGN

REQUEST A CONFIGURATION

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions