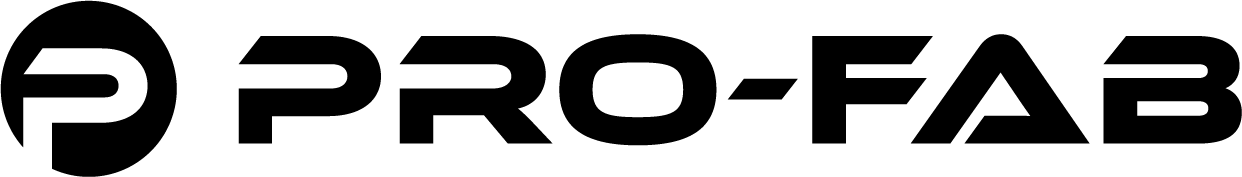

EDF FEEDER

ULTIMATE FLEXIBILITY, VALUE, AND CONTROL

WHY EDF FEEDER?

VERSATILE OPERATION

FLOW CONTROL

SANITARY & MAINTENANCE FRIENDLY

Product Features

-

Feed, meter, screen, and lane a variety of food products

-

Stand alone or fully integrated into various systems and solutions

-

Uniform and accurate product flow with solid state controls

-

Food-grade sanitary design with electro-mag drives and wipe down pans

SPECS

Key details to help you decide if the EDF Feeder is right for your operation.

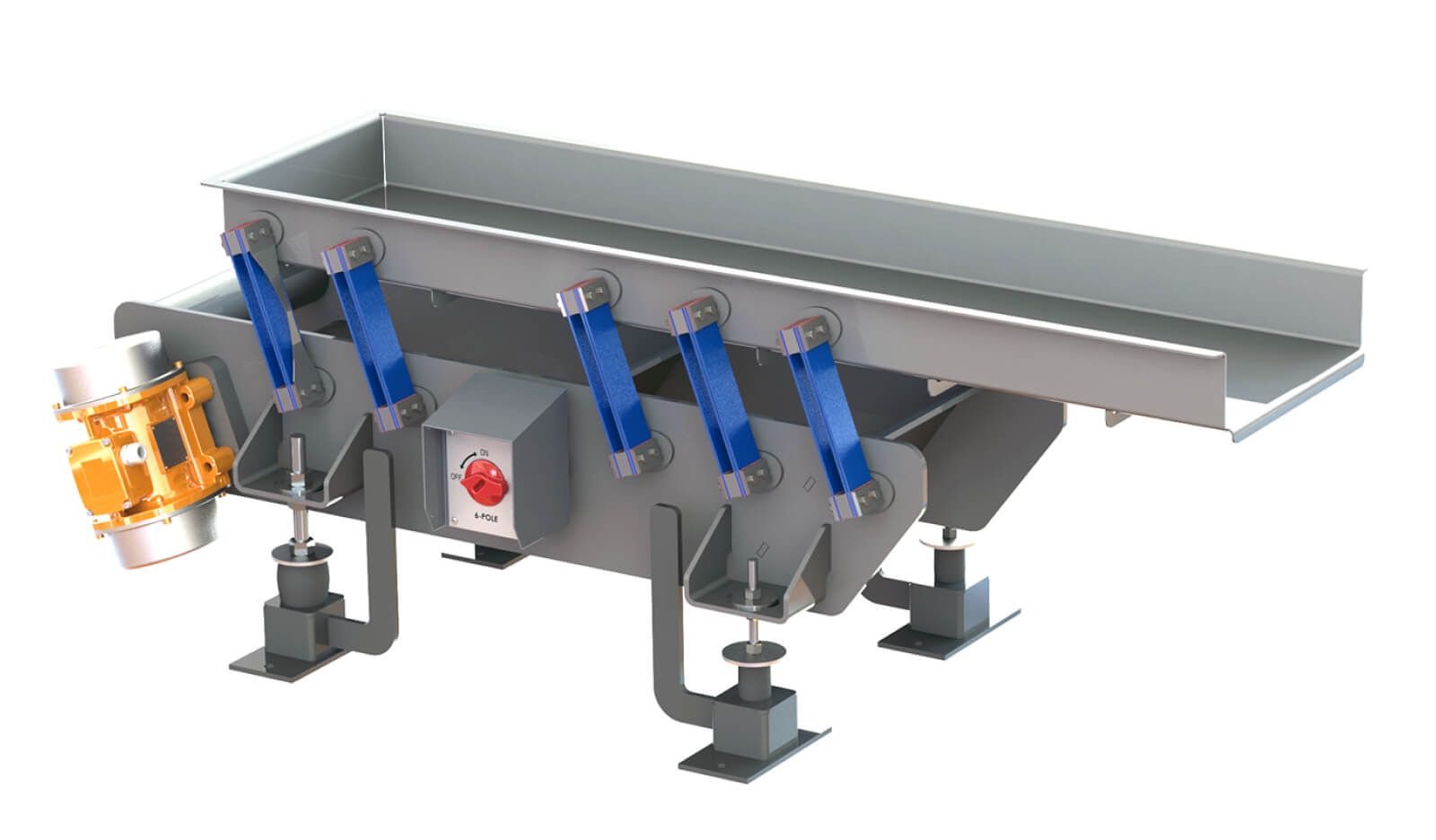

Electromagnetic drive

Simple, solid state controls

Troughs/pans: stainless steel, wire mesh, perforated, or solid

Width

3-72” (76-1829 mm)

Length

12-120” (305-3048 mm)

Overhang Length

18” (457 mm) standard

Depth

up to 8” (203 mm) standard

Electrical

120 V/1 Ph/60 Hz

Options

Additional equipment options to customize the EDF Feeder precisely to your application.

- Wipe down sanitation level

- Floor, platform, or ceiling mounted

- Discharges – fixed, manual, single or dual

- Divided trough for multiple lanes and products

Service & Parts

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to seamlessly integrate the line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

- Reach a real-life person to answer questions or take a part order

COMMON FOOD INDUSTRIES

The EDF Feeder efficiently feeds bulk product throughout your processing line. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

SANITARY DESIGN

We put sanitation and food safety at the forefront of our designs. The EDF Feeder is designed for maximum accessibility and ease of washdown, in line with food processing equipment standards.

REQUEST A CONFIGURATION

Ready to get started on your configuration? Contact us to customize the EDF Feeder to your application, layout, and processes.

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions