Blog

How Design Impacts Sanitary Conveyor Safety, Efficiency & Compliance

In food processing, reliable cleaning protocols are non-negotiable. Every plant has them, and every sanitation team knows the drill. But even with the most experienced crew and best SOPs, cleaning effectiveness often hinges on something that’s less talked about: the design of the equipment itself.

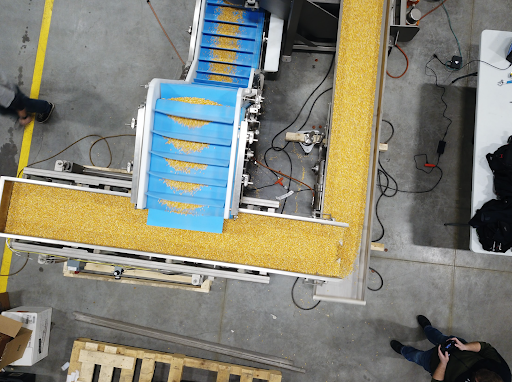

When conveyors are hard to clean, everything suffers: food safety, shift timing, labor resources, and audit readiness. That’s why at PFI, we design sanitary conveyors that perform well on the line and can be cleaned quickly, thoroughly, and consistently.

WHY CLEANABILITY STARTS WITH DESIGN

Processors don’t struggle because they don’t know how to clean. They struggle when equipment design makes proper cleaning difficult, time-consuming, or inconsistent.

Flat surfaces, hollow tubing, difficult-to-remove guarding, and tight, inaccessible corners all create sanitation bottlenecks — and they’re more common than many OEMs care to admit. Even when protocols are followed to the letter, designs like these can undermine cleaning outcomes, turning sanitation into a time-consuming, risky process.

By contrast, conveyors designed with sanitation in mind reduce reliance on perfect human execution. They create repeatable, faster, and more effective outcomes — and that makes all the difference.

WHAT GOOD SANITARY DESIGN LOOKS LIKE

The best cleaning outcomes for food processing lines are engineered upstream. At PFI, we’ve refined every detail to ensure that cleaning, validation, and maintenance are seamless, not a scramble. Examples include:

- Open-frame designs improve visibility and access during washdowns

- Sloped framework helps water drain completely, minimizing the risk of pooling and bacterial growth

- Designs without hollow tubing and minimal flat surfaces, both of which are notorious harborage points

- Tool-less maintenance where possible

Even elements like guarding and component access are reimagined. Instead of requiring tools or disassembly manuals, our conveyors feature tool-less belt lifts, flip-up guards, and quick-disconnect components — because sanitation windows are short and labor demands are high.

Where needed, we integrate clean-in-place (CIP) systems and belt scrapers to automate some of the most time-intensive parts of cleaning. It’s all designed to support your team — not slow them down.

TIME, LABOR, AND RISK: THE HIDDEN COST OF POOR DESIGN

Every extra minute spent cleaning is a minute lost to production. Multiply that across multiple shifts, machines, and changeovers, and the true cost becomes clear.

Hard-to-clean conveyors require more downtime, more labor, and more rework. Worse, they increase the chance of failed swab tests, missed residue, and food safety risks that aren’t always caught until it’s too late.

Compare that to a conveyor system that’s engineered for sanitation. Cleaning cycles are faster. Labor is reduced. Microbial validation becomes simpler. And because the design supports compliance, your food safety teams can work more confidently.

DESIGNED FOR VALIDATION AND AUDITS

It’s not just about how clean your equipment looks. It’s about how clean it tests. Swab testing is one of the biggest pressure points for food safety managers. When conveyors are hard to access or include hidden surfaces, it becomes more difficult to confirm cleanliness and more likely that issues will arise during audits.

PFI conveyors are built to make validation easier. With accessible product contact surfaces, polished welds, and minimal harborage points, sanitation crews can work faster — and swab testing becomes more consistent. We design to meet or exceed FSMA, USDA, and AMI guidelines across industries, including meat, dairy, produce, bakery, snacks, and pet food.

A LOOK AT CONVEYOR TYPES AND THEIR SANITARY FEATURES

Every conveyor style brings its own sanitation challenges. Our designs are tailored to meet them head-on.

Belt conveyors, for instance, often require disassembly to access rollers, frames, and underside areas. PFI belt systems are built with tool-less belt lifts, sloped support structures, and optional belt scrapers that reduce cleaning time without compromising access.

Vibratory conveyors (already one of the easiest systems to sanitize) are enhanced by PFI’s fully welded pans and open architecture. No belts, minimal moving parts, and optional pan-lift designs mean faster, more reliable sanitation.

Horizontal motion systems like our PURmotion conveyor are ideal for fragile or seasoned products, and we’ve engineered them with reduced complexity and open-frame access, making cleaning and inspection intuitive.

For bucket elevators, where chains, buckets, and vertical housings create additional cleaning demands, we’ve implemented quick-change buckets, stainless construction, and open access around high-contact zones.

TAKE A CLOSER LOOK AT YOUR CONVEYOR SYSTEM

If cleaning feels like a constant battle, or if your swab tests are inconsistent despite a trained crew, your equipment may be part of the problem. At PFI, we design conveyors that are easier to clean, faster to validate, and built to support the standards your facility needs to uphold.

Talk to an engineer on our team to schedule a sanitary design consultation or explore how PFI equipment can strengthen your food safety performance.

Related Resources

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions