CANDY & CONFECTIONERY

OPTIMAL PRODUCT HANDLING AND SAFETY IS A SWEET TREAT FOR PROCESSORS

BUILT FOR THE THINGS CANDY PROCESSORS CARE ABOUT

OPTIMAL PRODUCT HANDLING

DEPENDABLE, HIGH-VOLUME OPERATION

INTEGRATION-READY

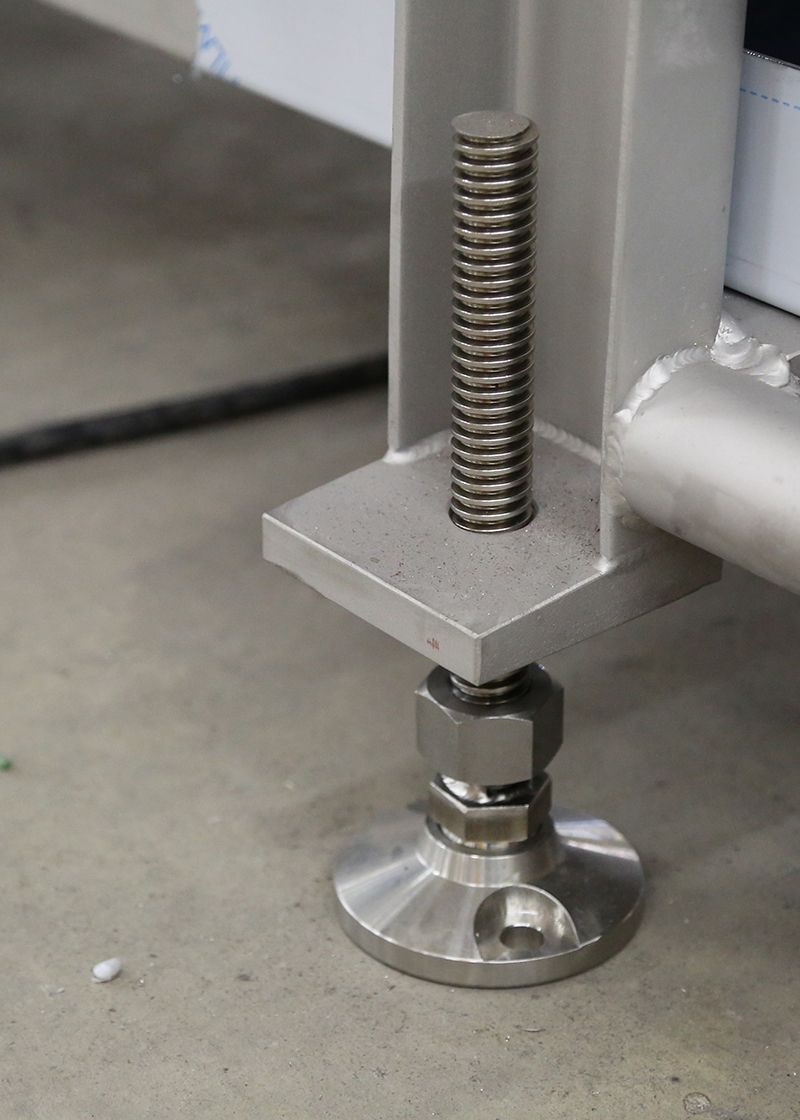

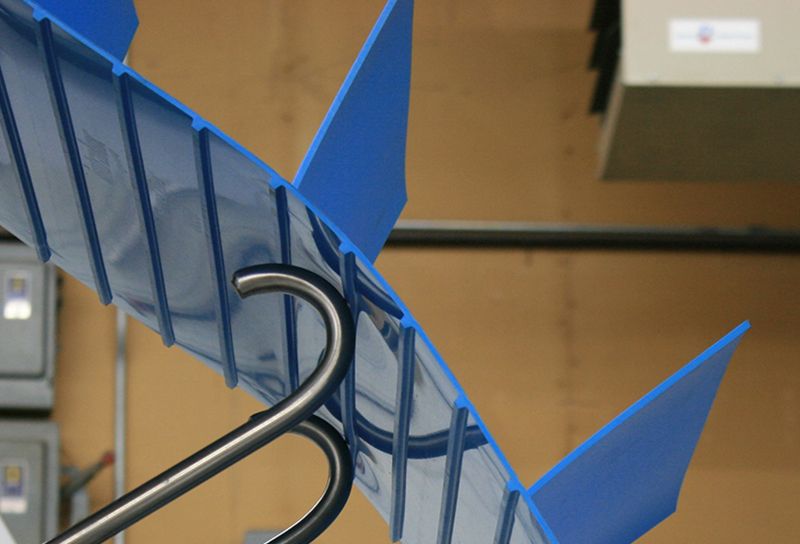

SANITARY DESIGN

CANDY PRODUCTS

-

Chews

-

Chocolate

-

Gum

-

Gummies

-

Hard Candy

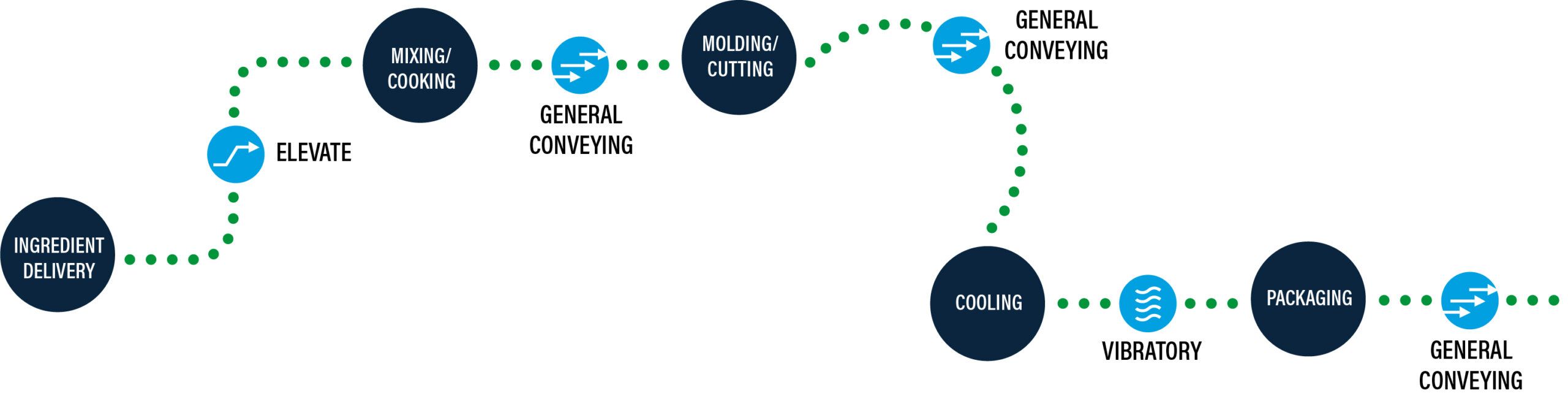

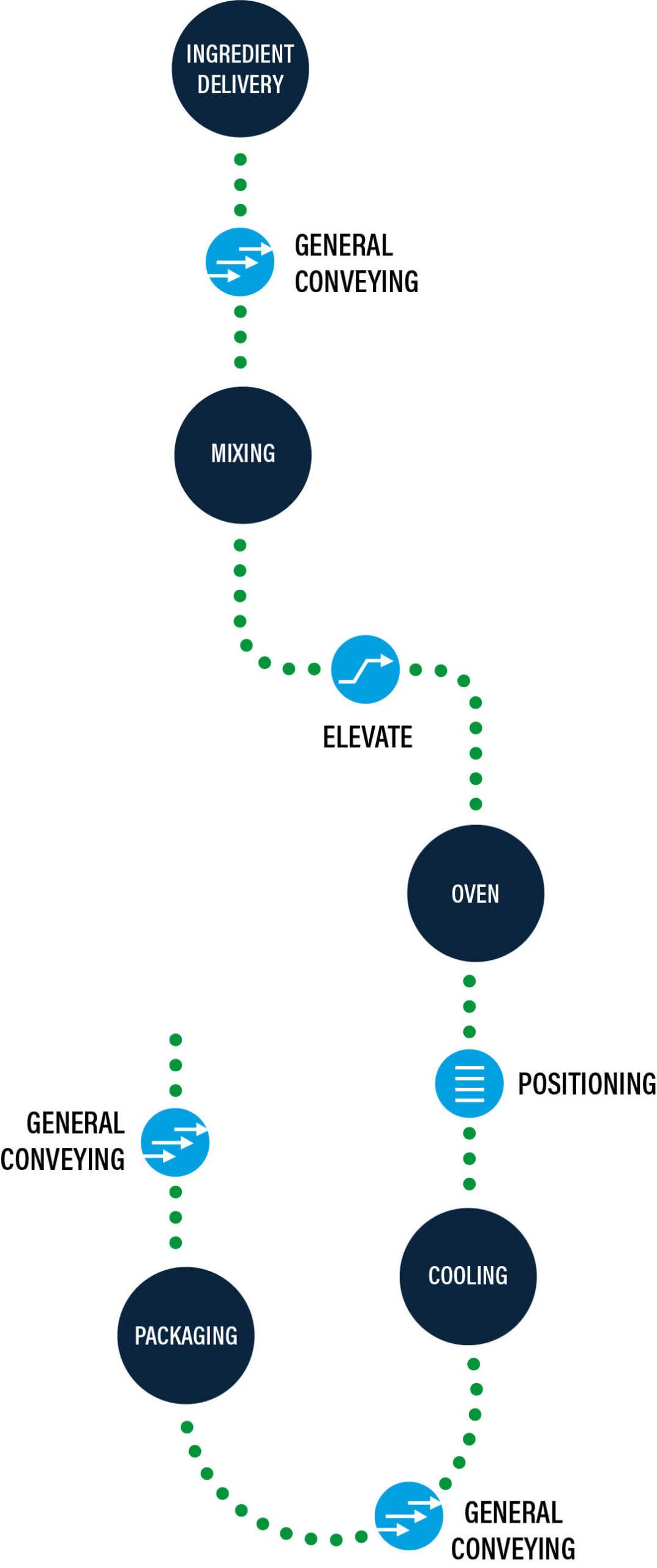

CONNECT ALL OF YOUR KEY PROCESSES

We design and manufacture conveying and handling systems that integrate the key processes of your candy and confectionery line. We regularly partner with your other OEMs for mixing, baking, cooling, weighing, and packaging so you get the best line possible configured precisely to your layout and a seamless project from start to finish.

CANDY APPLICATIONS

Equipment Categories

Our core sanitary conveying and handling equipment falls into the following categories. Visit our full equipment listing for information on dumpers and other systems.

FULL SYSTEM SUPPORT

Trust PFI to design and manufacture the complementary structures you need around your key processes. From stairs to platforms, we put the same craftmanship into integrating and supporting your entire line.

COLLABORATIVE APPROACH

PFI collaborates with your engineering, operations, safety and maintenance teams, as well as other OEMs, and engineering firms to ensure our conveying solutions fit and operate viably from the word go.

FIND THE RIGHT CANDY SANITARY CONVEYING & HANDLING EQUIPMENT FOR YOU

PFI equipment has been proven in candy and confectionery processing for decades. Our machines are durable, sanitary and enable processors to improve efficiency, maintain product quality and safety, and grow their business. Choose from our full machine catalog below or contact us to configure a system or solution just for you.

EDF Feeder

Feed, screen, and lane product accurately with this versatile vibratory feeder. Use on its own or with a Hopper Feeder or Mix-Blend System.

Horizontal Belt Conveyor

Connect your processing line with flat-bed conveyors built for your exact layout with a range of belt options.

Mix-Blend System

The Mix-Blend System, its components and complementary conveyors give you consistently accurate mixed recipes by feeding multiple products together.

Design, Testing + Installation

REQUEST A CONFIGURATION

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions