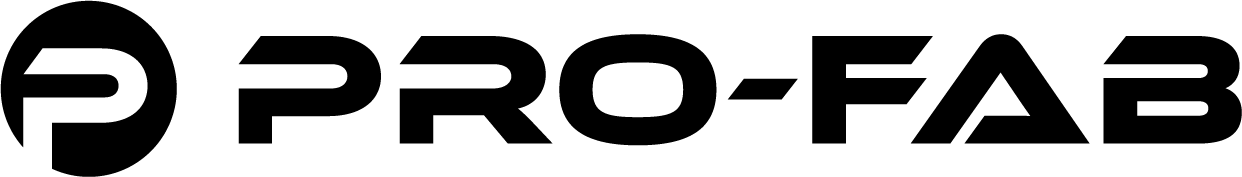

VIBRAflex II

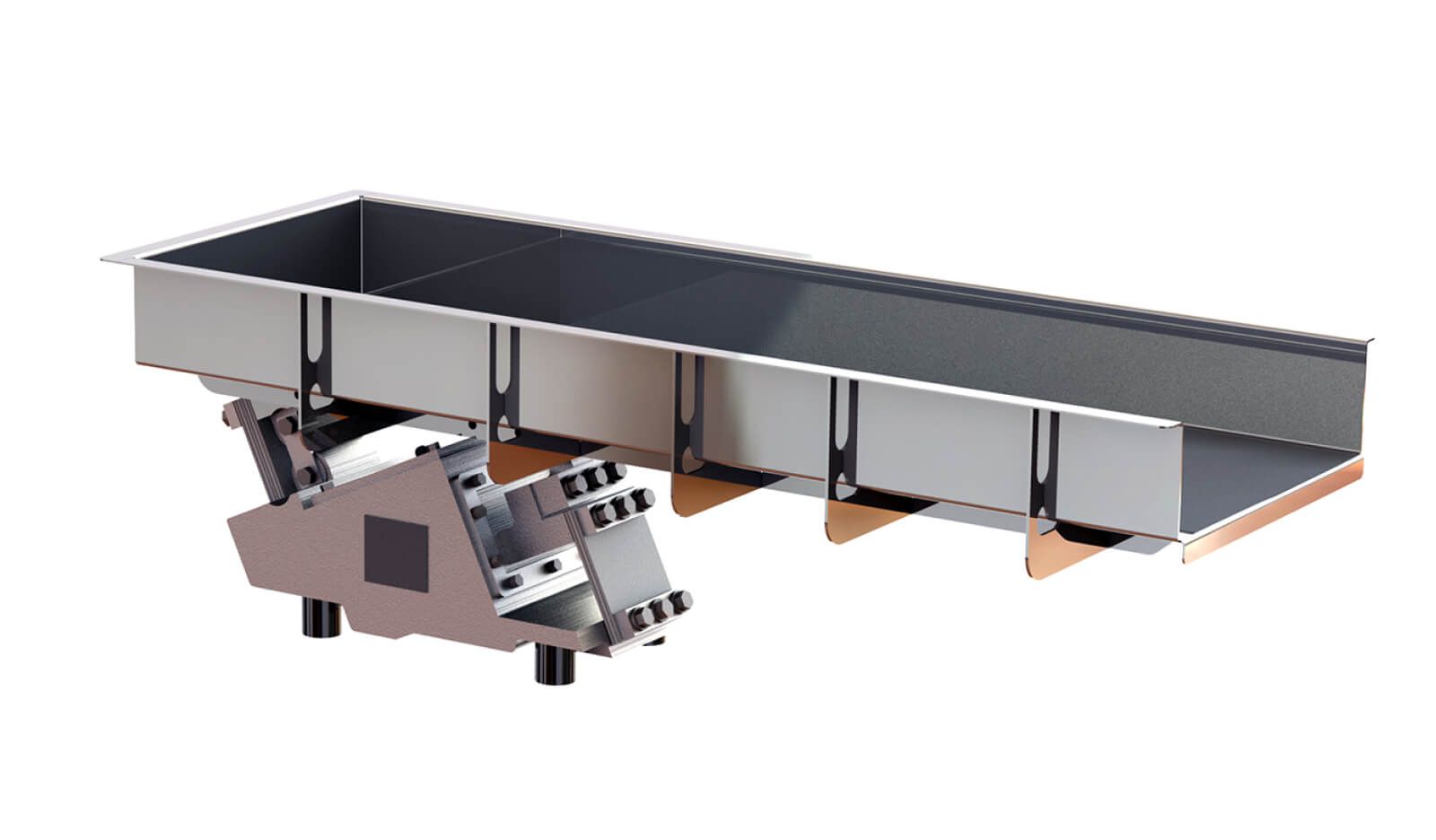

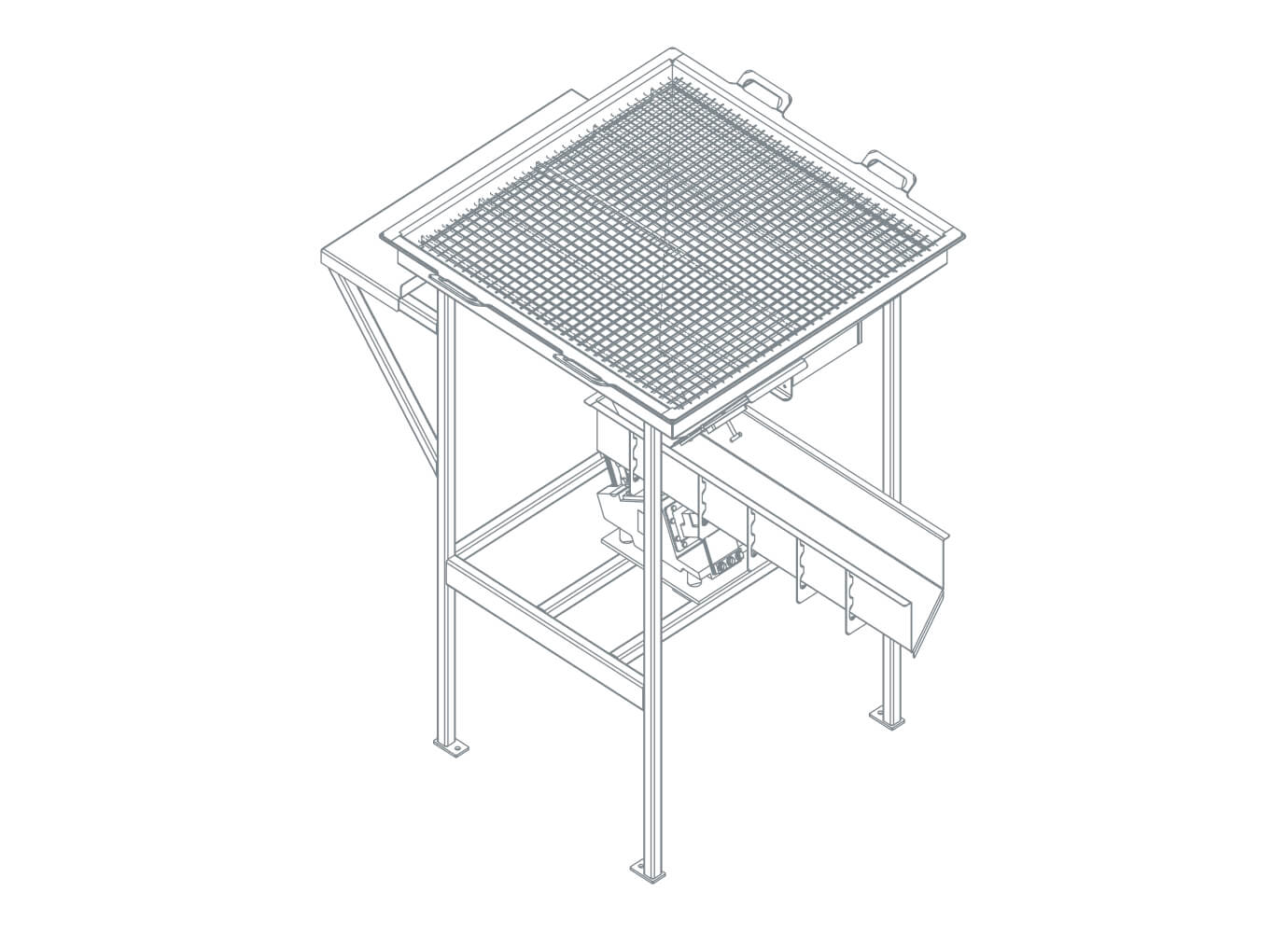

VFII (VIBRAflex II)

ULTIMATE FLEXIBILITY, VALUE, AND PERFORMANCE

Efficiently move a high volume of product throughout your line in a smaller footprint, across a range of applications, with a reduced total cost of ownership.

WHY VFII?

The VIBRAflex II (VFII) offers the ultimate flexibility and value for food processors with its various applications throughout the entire processing line, efficient operation, and sanitary and maintenance-friendly design. Get operation and maintenance-friendly vibes with the VFII.

-

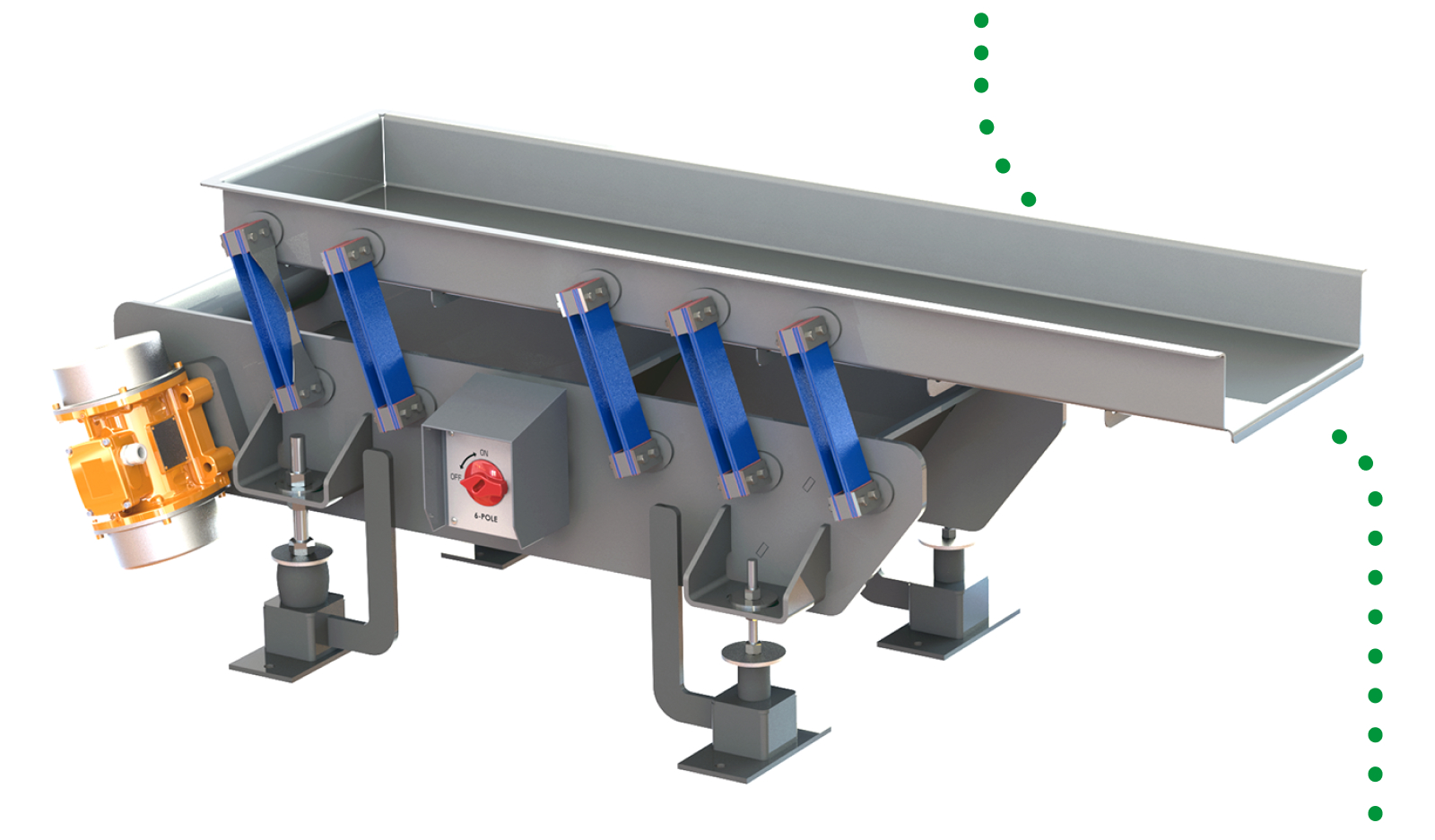

VERSATILE OPERATION

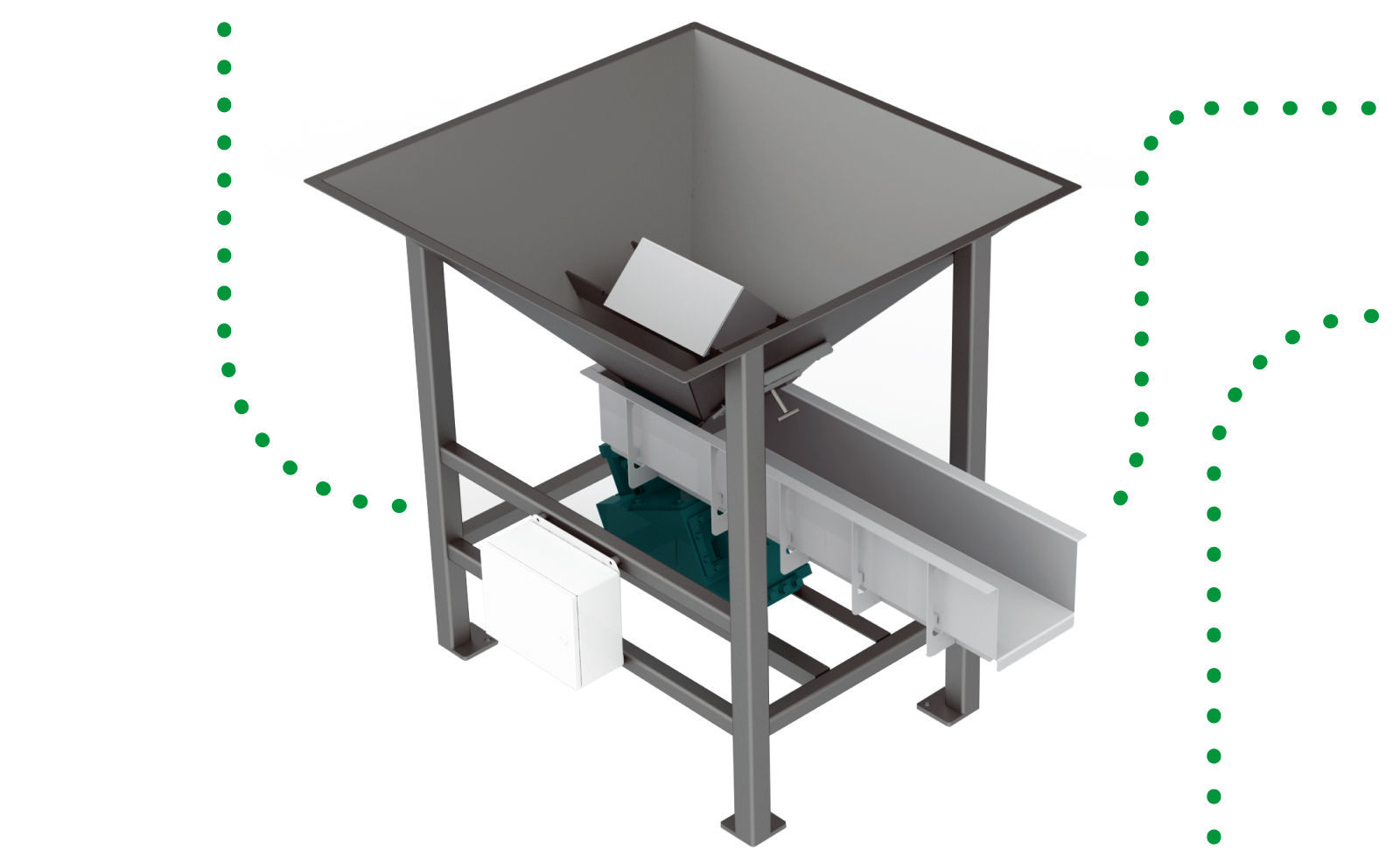

Use the VFII to screen, lane, grade, feed, spread or dewater/shake product between the key processes on your line across a wide range of temperatures.

-

OPTIMAL PRODUCT INTEGRITY

Get gentle product handling and accurate orientation with simple and precise vibration tuning.

-

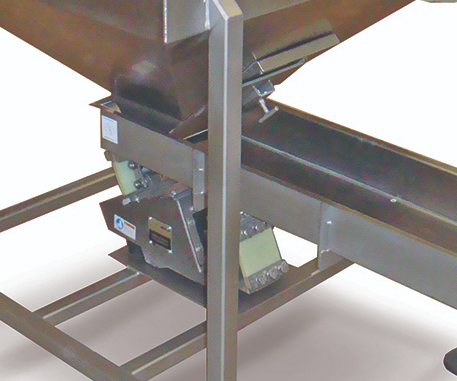

LOW MAINTENANCE SANITARY DESIGN

Featuring an excited base, no moving parts or lubrication, lower energy usage and noise, and virtually no maintenance. Easily wipe down or washdown pans for quick cleaning.

Product Features

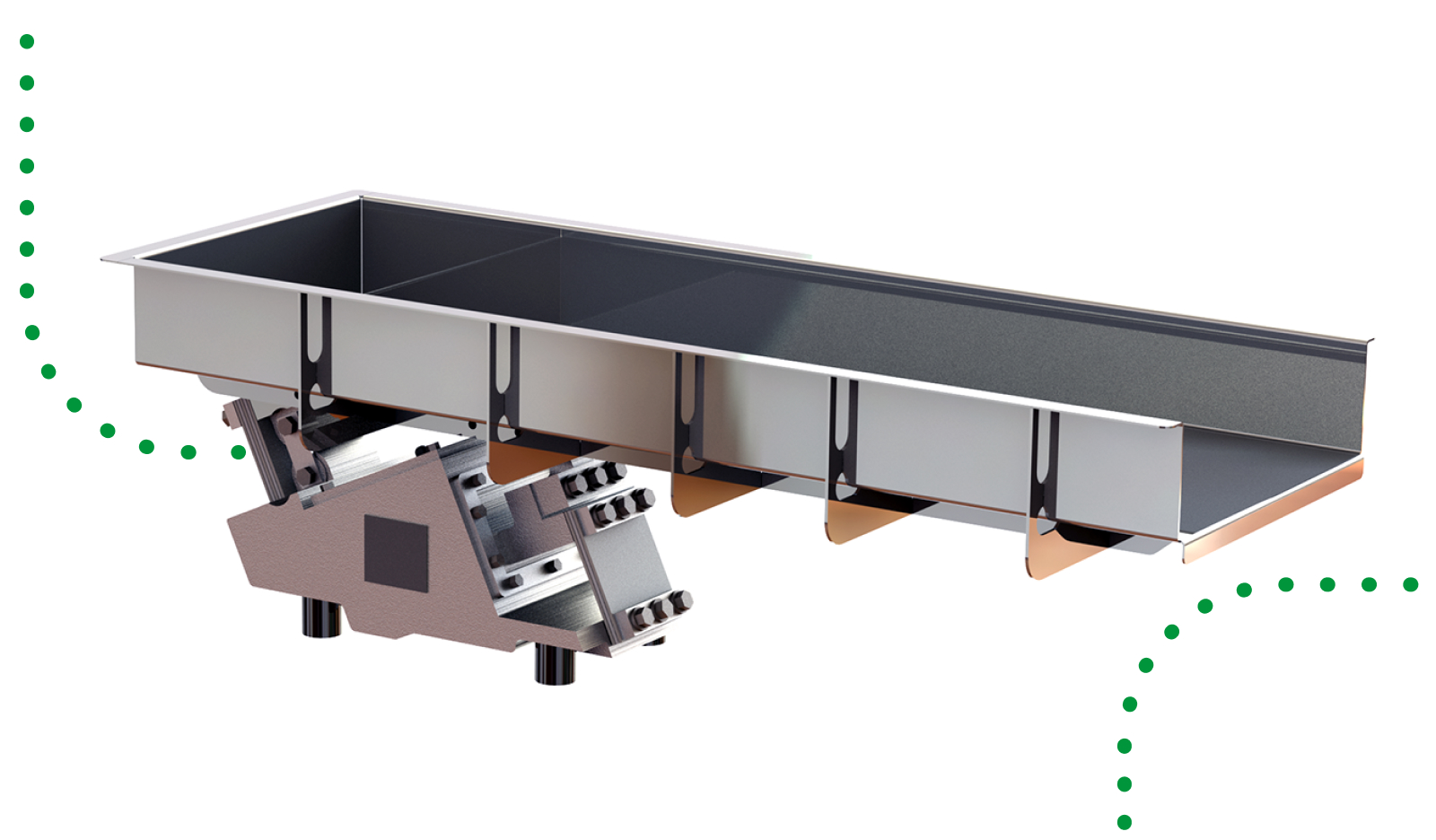

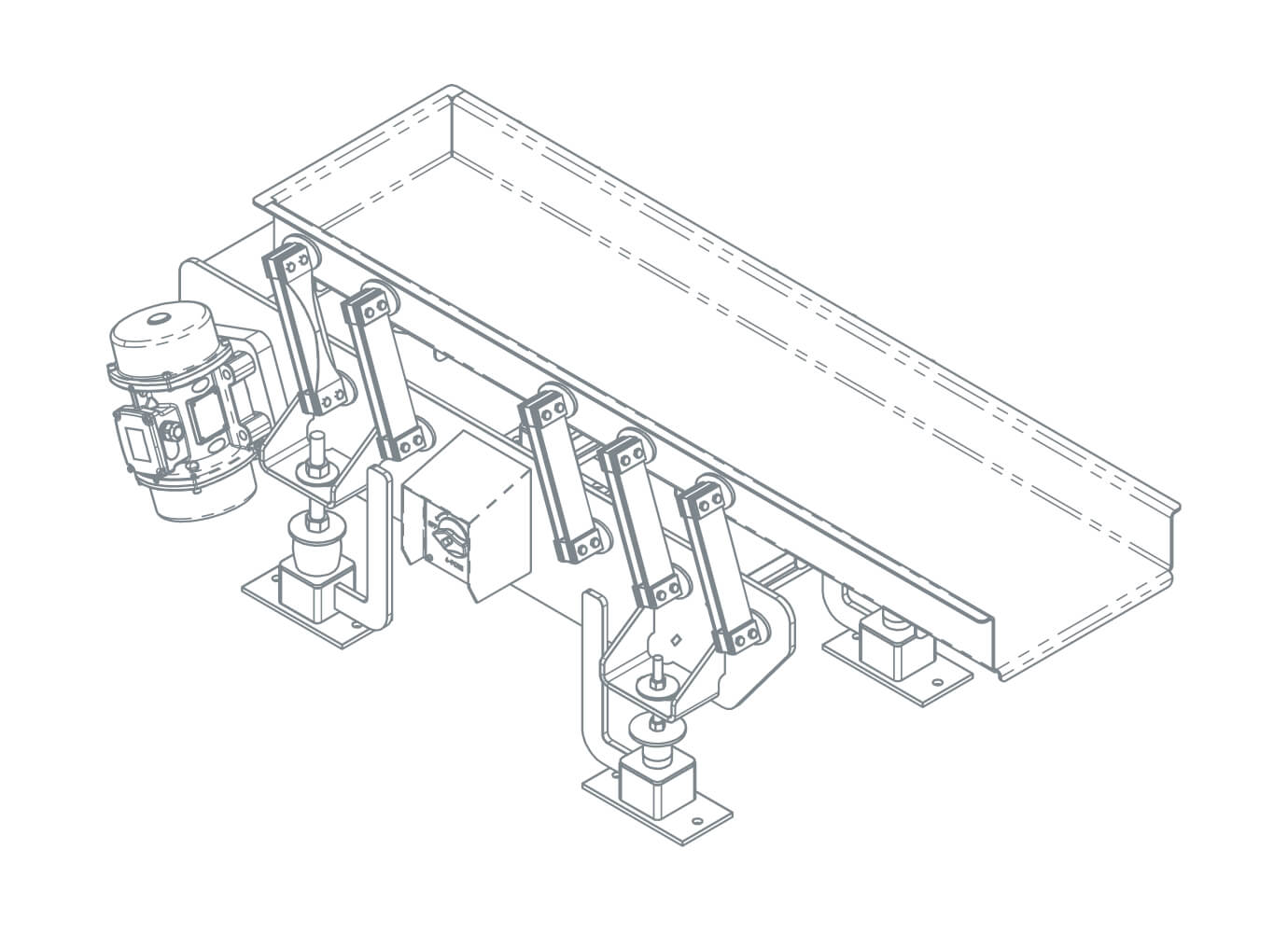

The VFII sanitary vibratory conveyor efficiently and seamlessly moves a variety of products throughout your food processing line. Its flexible for multiple value-added applications, such as screening, shaking, laning, grading, and spreading. Its excited base frame design eliminates external moving parts and lubrication, increases pan life, reduces power requirements, and significantly reduces noise. The VFII is built durably for long life, with features and options designed for all of your key operations, engineering, safety, and quality teams in mind.

-

Screen, shake, lane, grade, spread, and orientate a variety of food products across a range of temperatures

-

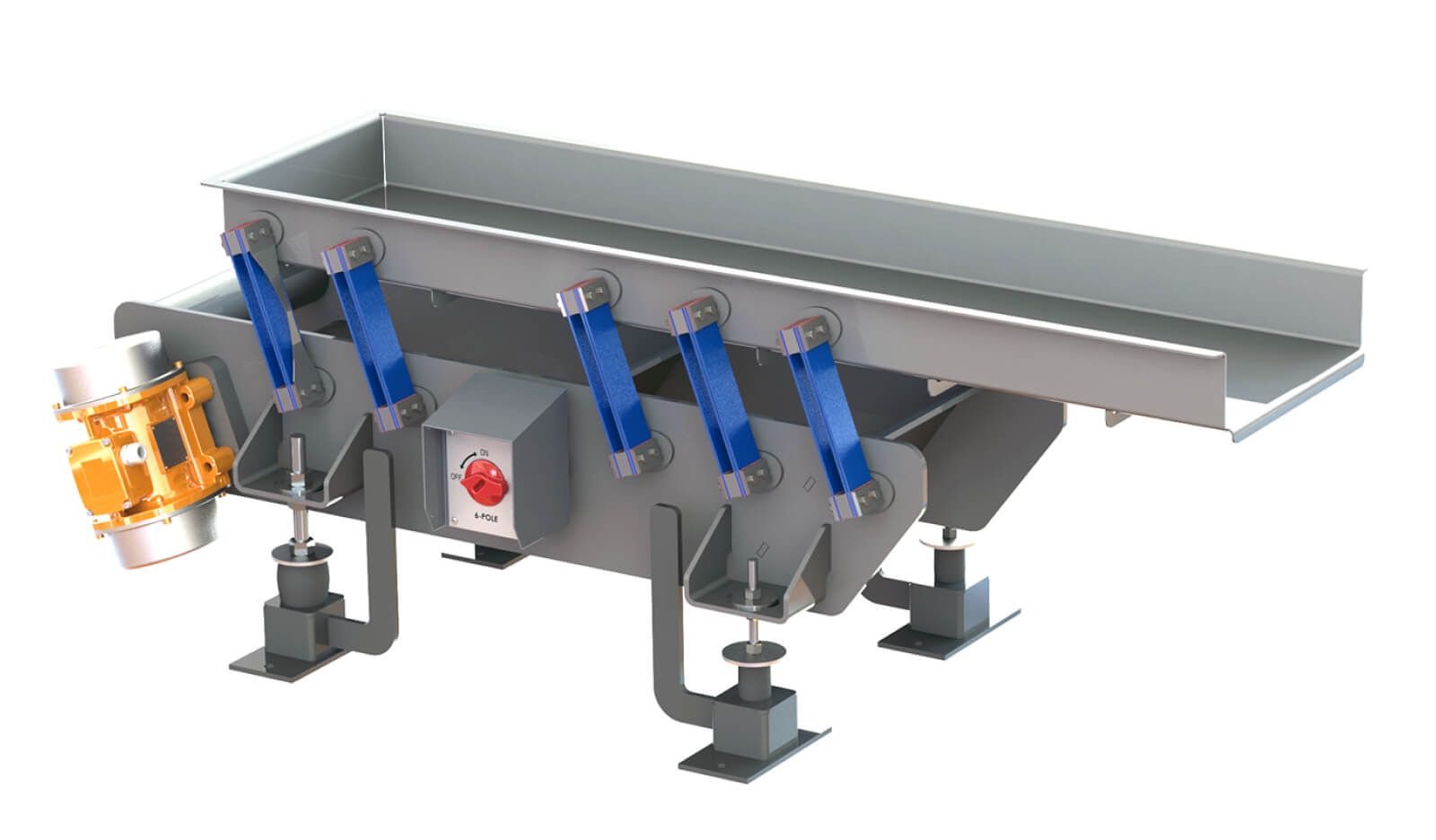

Excited base frame reduces stress, necessary horsepower, noise, and maintenance

-

Food-grade sanitary design with wipe down pans and no moving parts or lubrication

Equipment Information

SPECS

Main details to help you decide if the VFII is right for your operation.

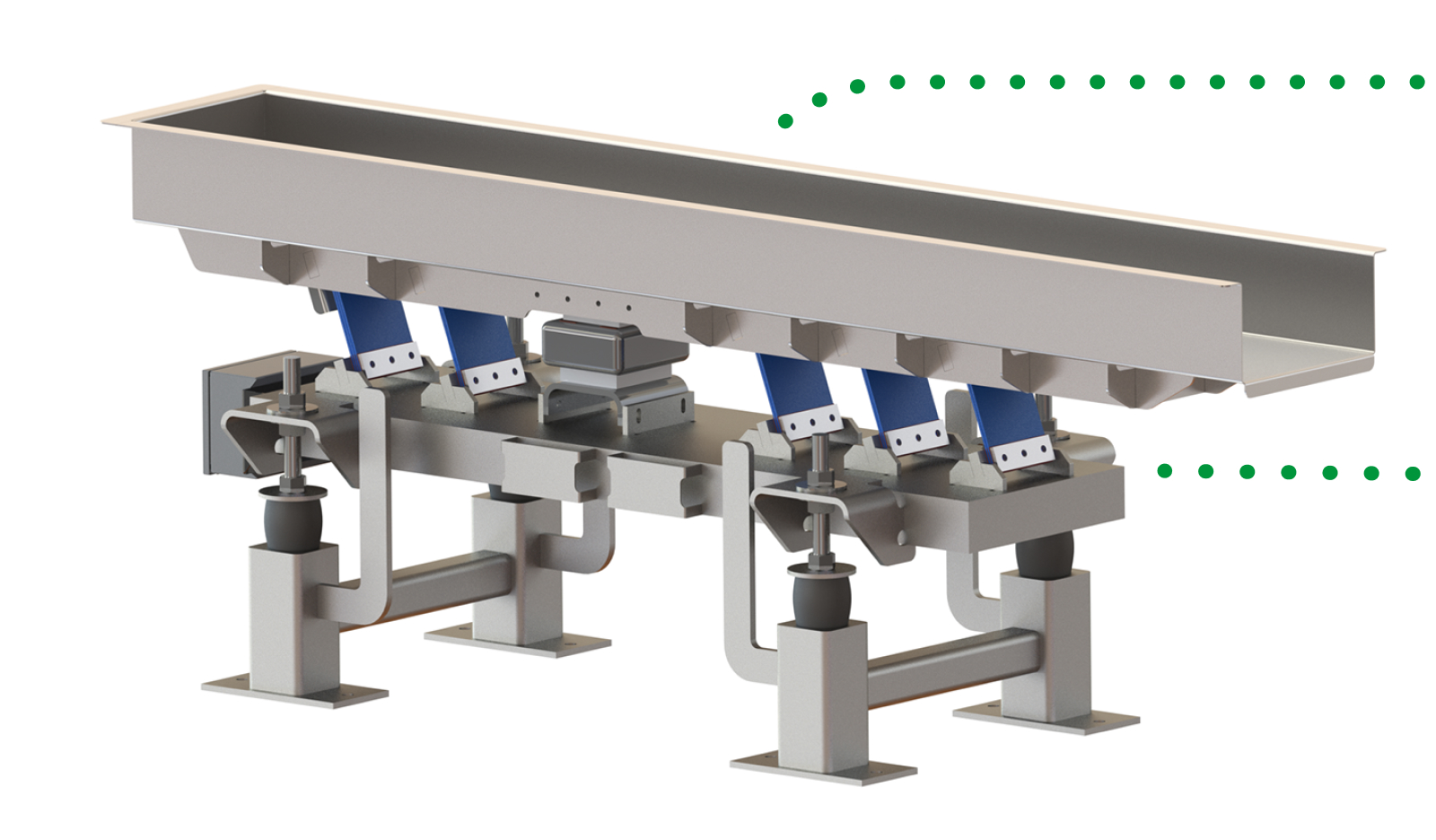

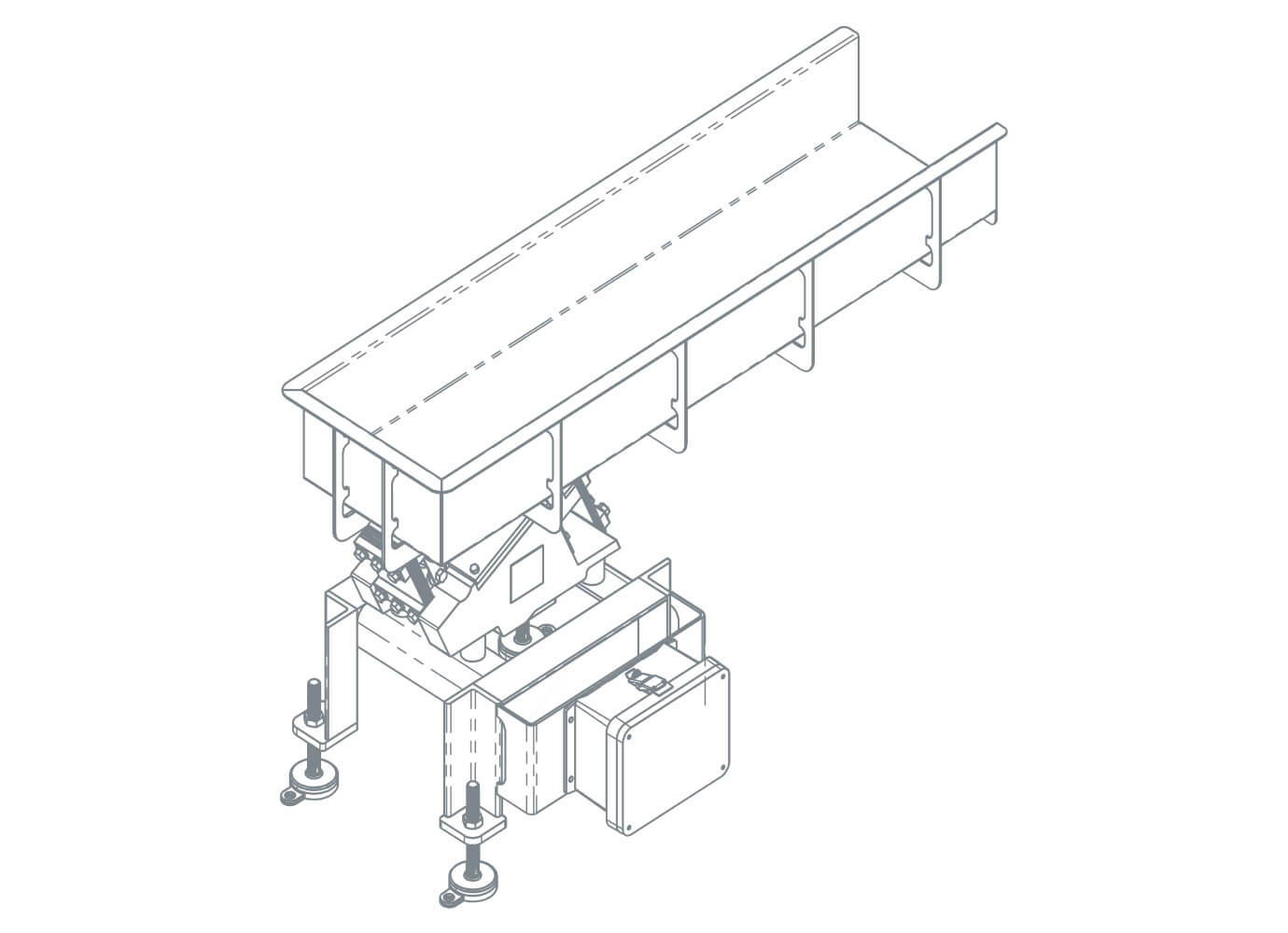

Vibra Drive mechanical drive

Excited base frame

Composite springs with welded spring mounts

Rubber isolators

Pans: stainless steel; wire mesh, perforated, or solid

Discharge end shapes: bias, flared, tapered, circular

Throw Angle

20 degrees standard

Width

12-72” (305-1829 mm)

Length

6-24’ (1.8-7.3 m), dependent on width

Depth

4” (101 mm) and up, application dependent

Electrical

230/460V/60Hz/3Ph

Options

Additional equipment options to customize the VFII precisely to your application.

- Floor, platform, or ceiling mounted

- Bottom slide gates – standard, dual, dust-tight, manual, pneumatic

- Side or end discharge

Service & Parts

Our expert project managers and technical service teams work hand-in-hand with you to find the solutions you need, quickly and efficiently, so you can stay up and running.

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to seamlessly integrate the line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

COMMON FOOD INDUSTRIES

Whether your product is wet or dry, sticky or abrasive, the VFII can efficiently convey it throughout your processing line. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

SANITARY DESIGN

-

From stainless steel construction to open frames to options to help easily access, clean, and validate.

From stainless steel construction to open frames to options to help easily access, clean, and validate. -

-

RELATED EQUIPMENT

REQUEST A CONFIGURATION

Ready to get started on your configuration? Contact us to customize the VFII to your application, layout, and processes.