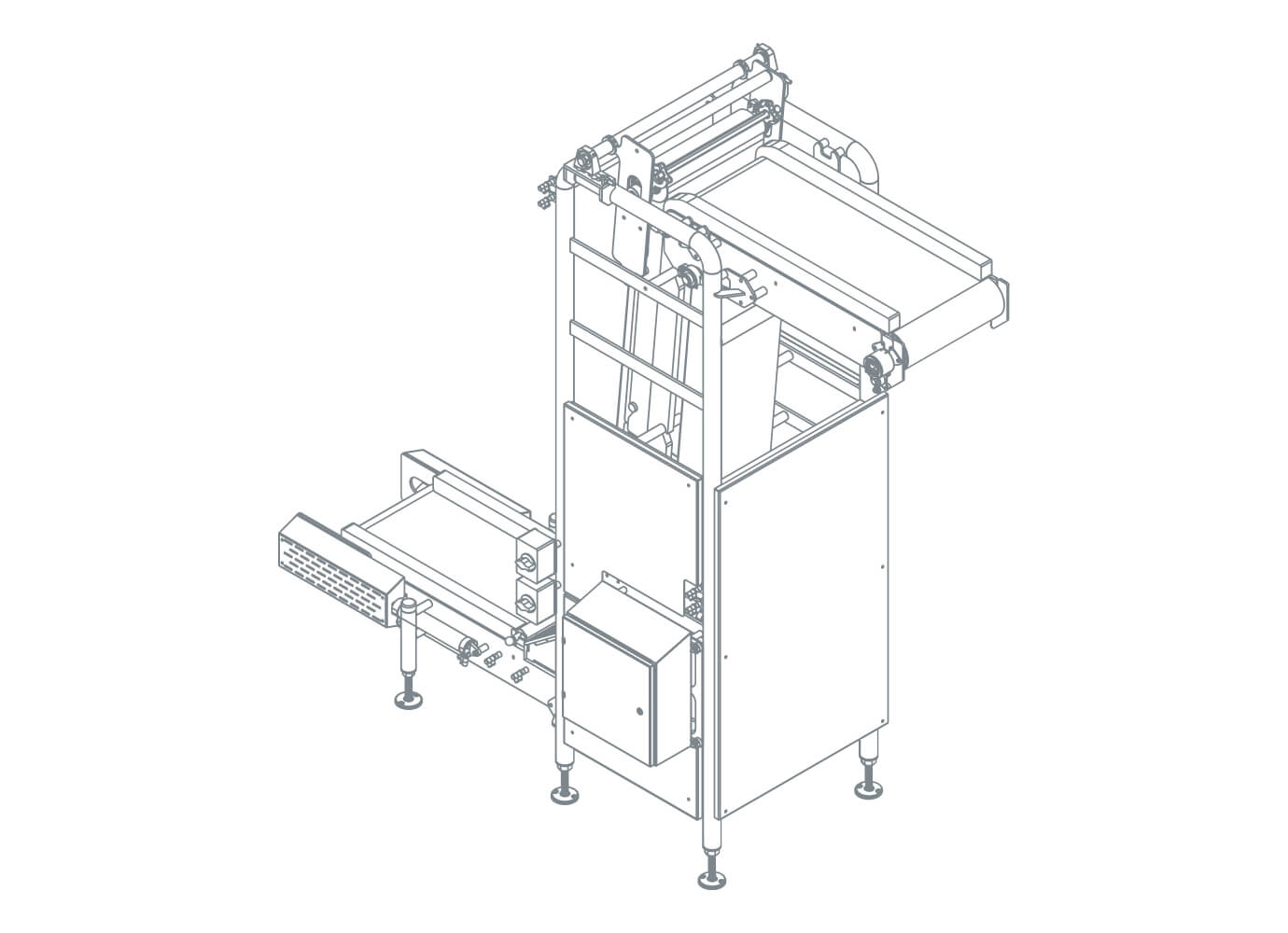

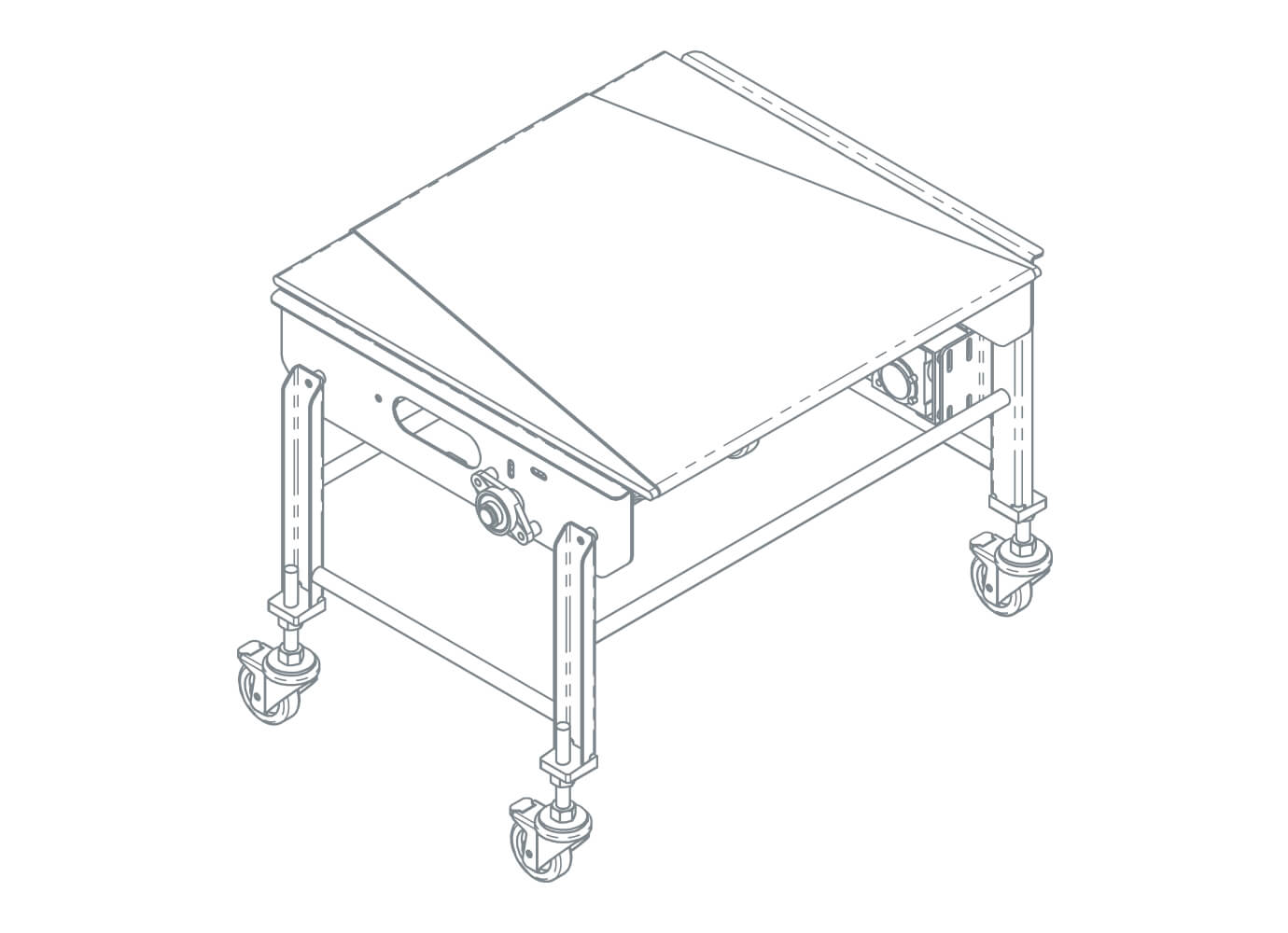

Spreader

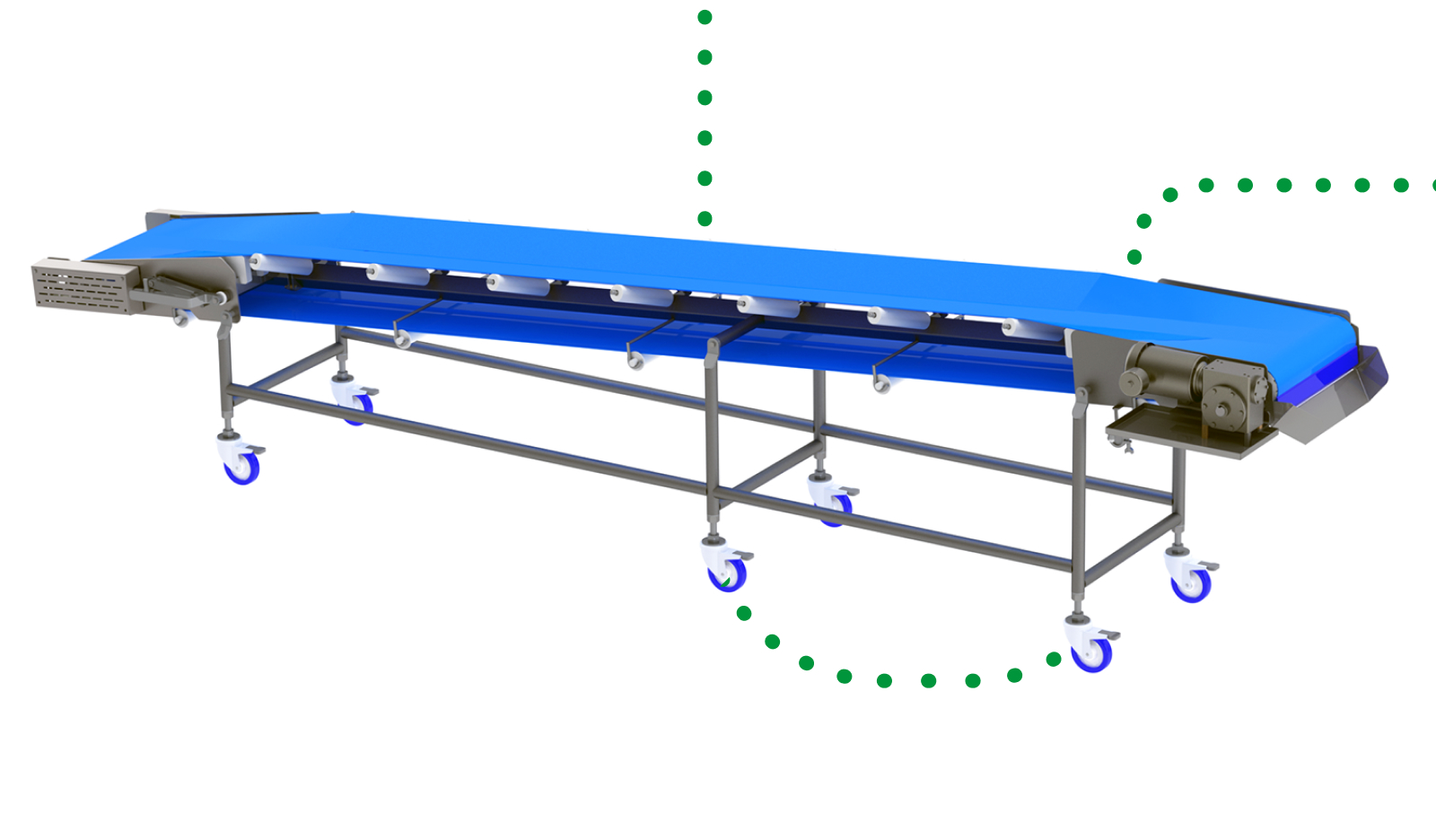

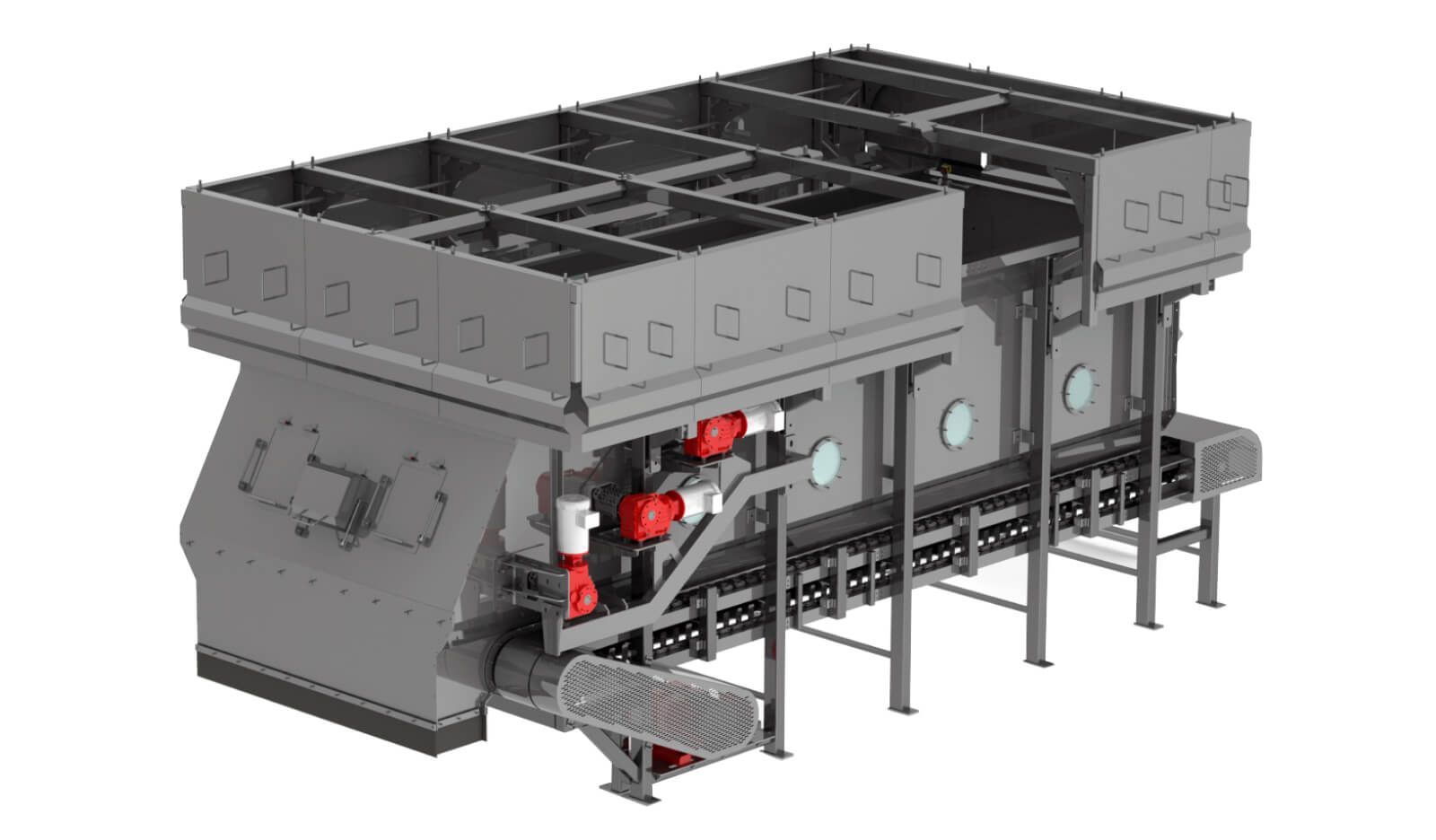

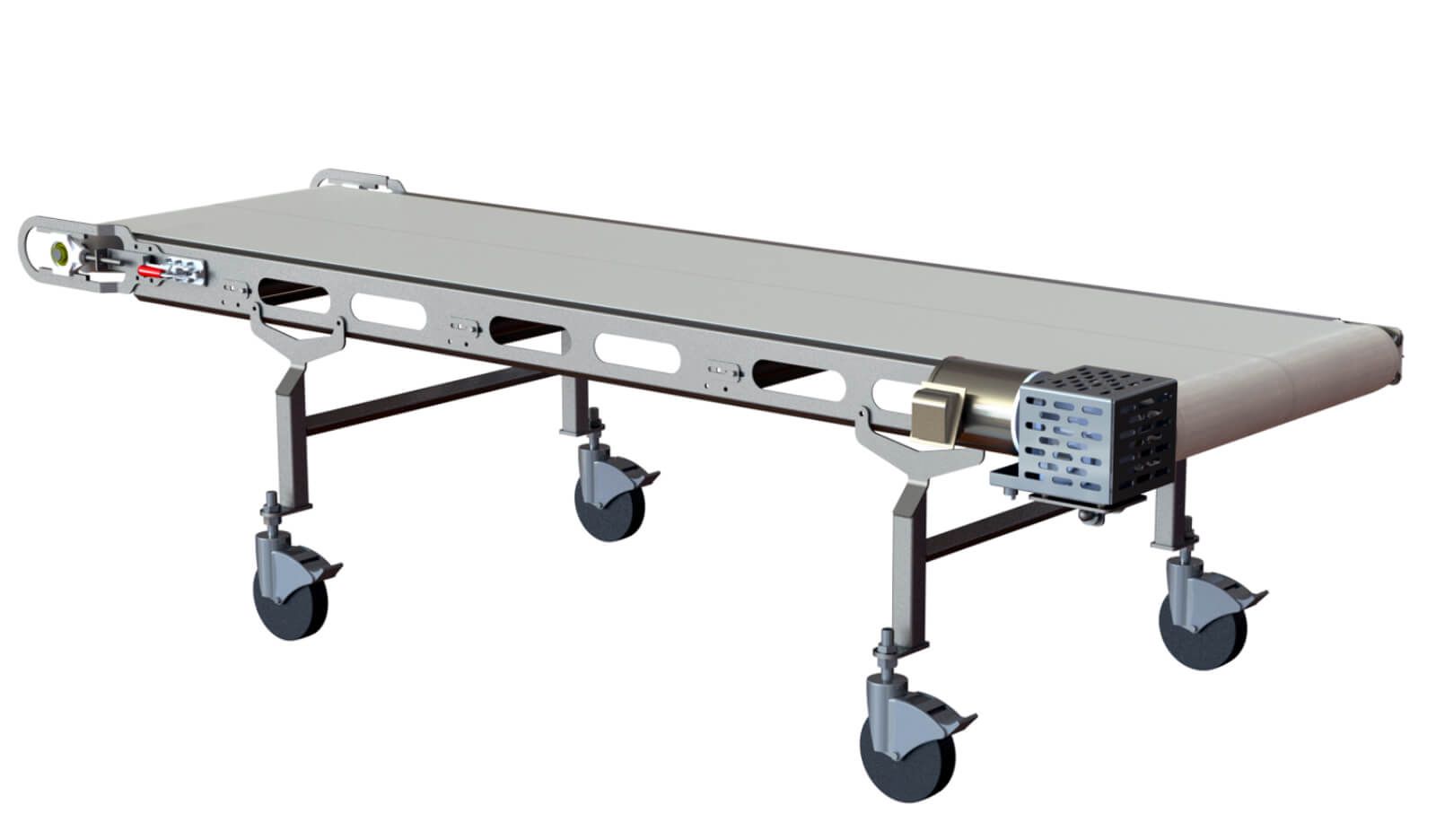

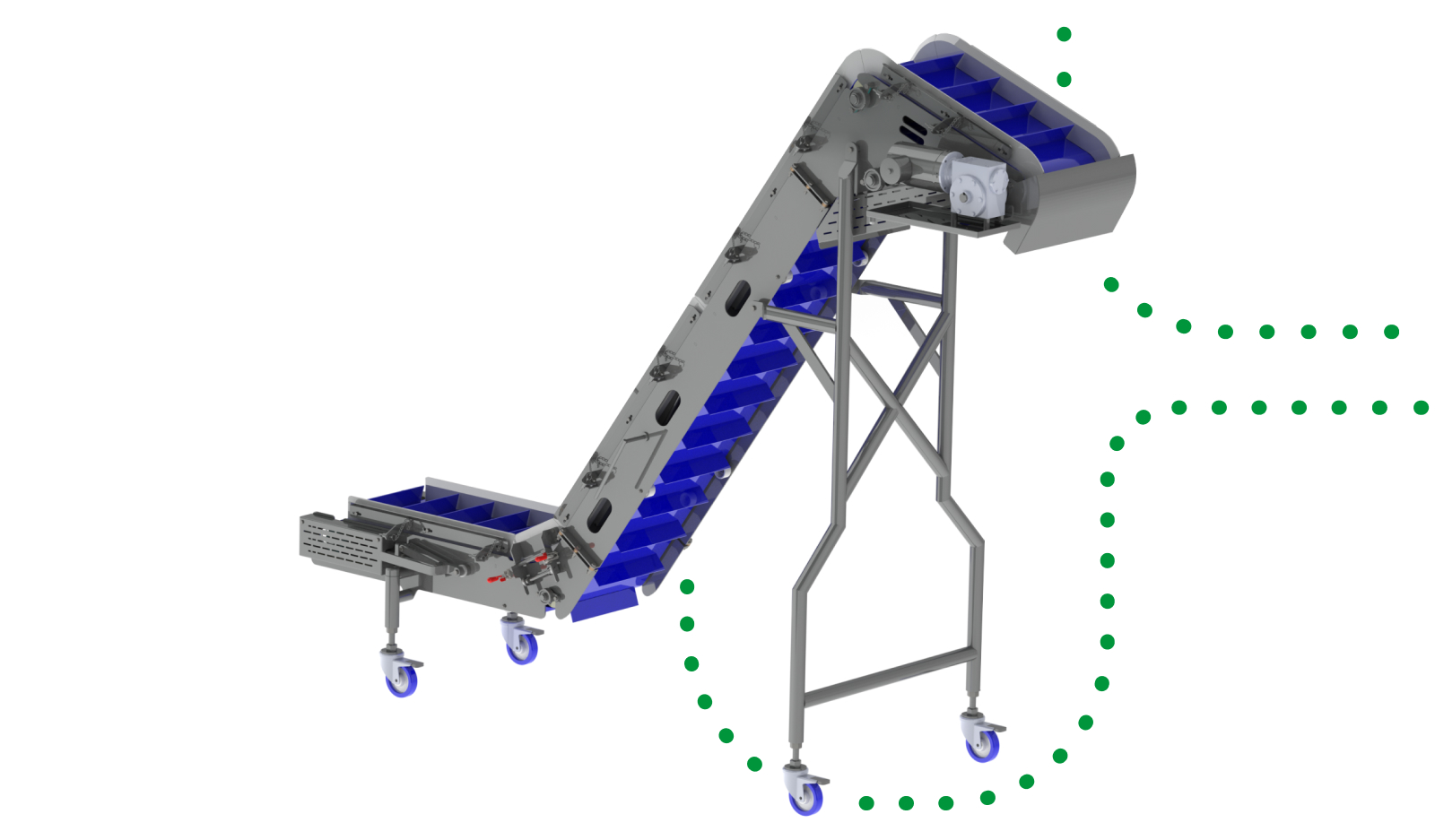

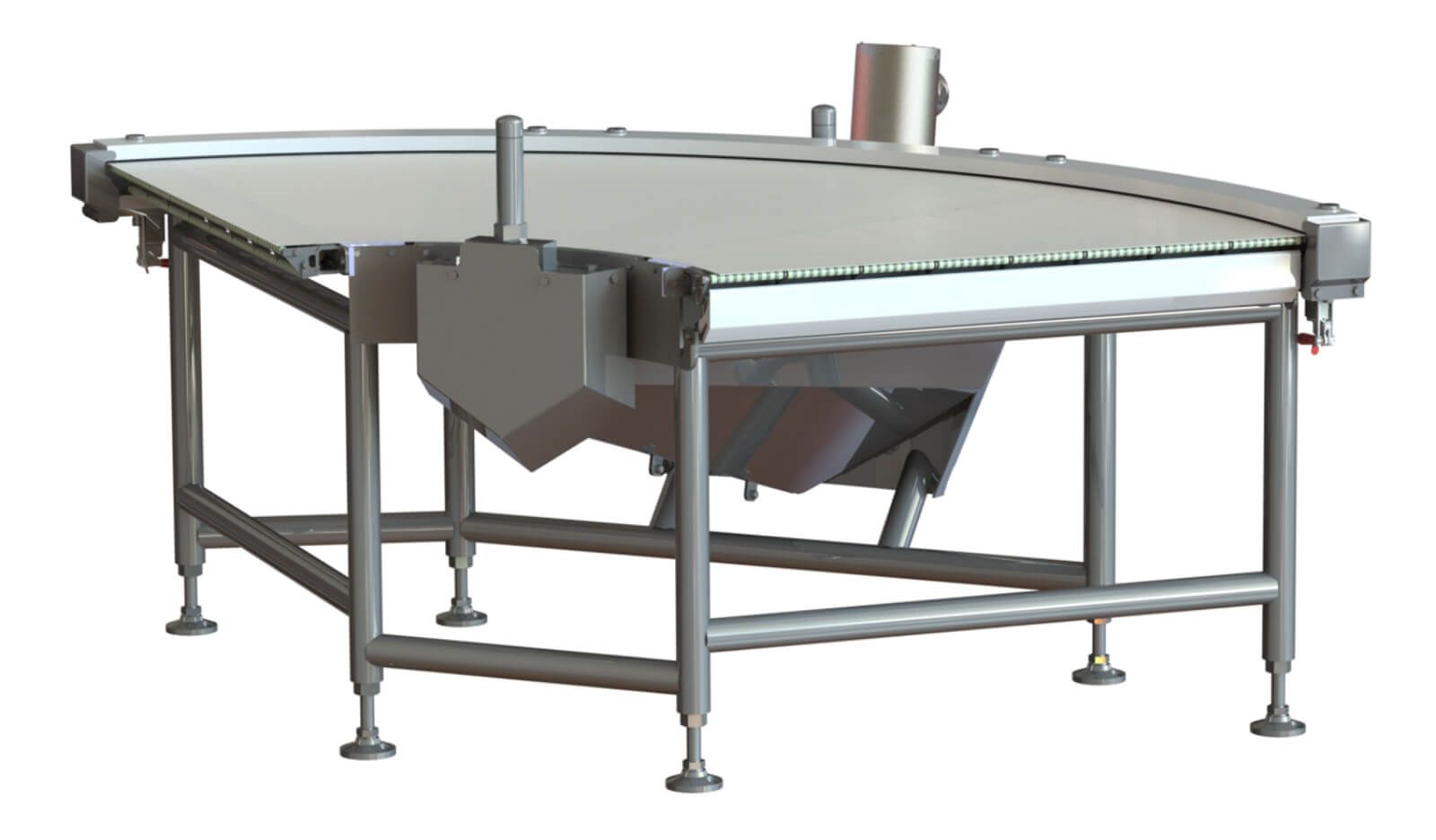

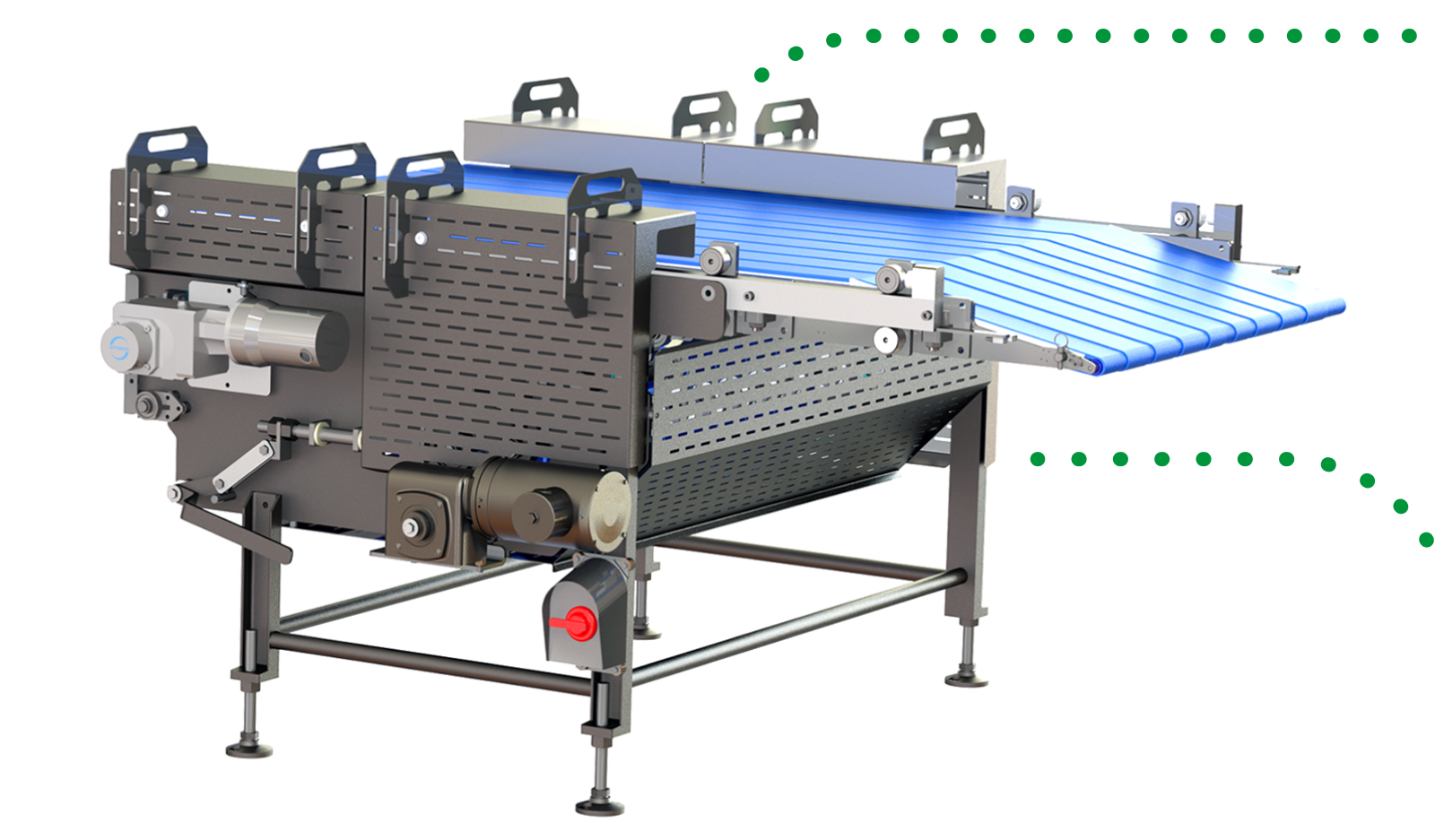

SPREADER CONVEYOR

CONNECT THE VARIOUS WIDTHS OF YOUR PROCESSING LINE

Seamlessly spread or converge product between processes while maintaining product orientation.

WHY THE SPREADER CONVEYOR?

The Spreader easily integrates your processing line by transferring product between narrower and wider belts with gentle handling and accurate positioning.

-

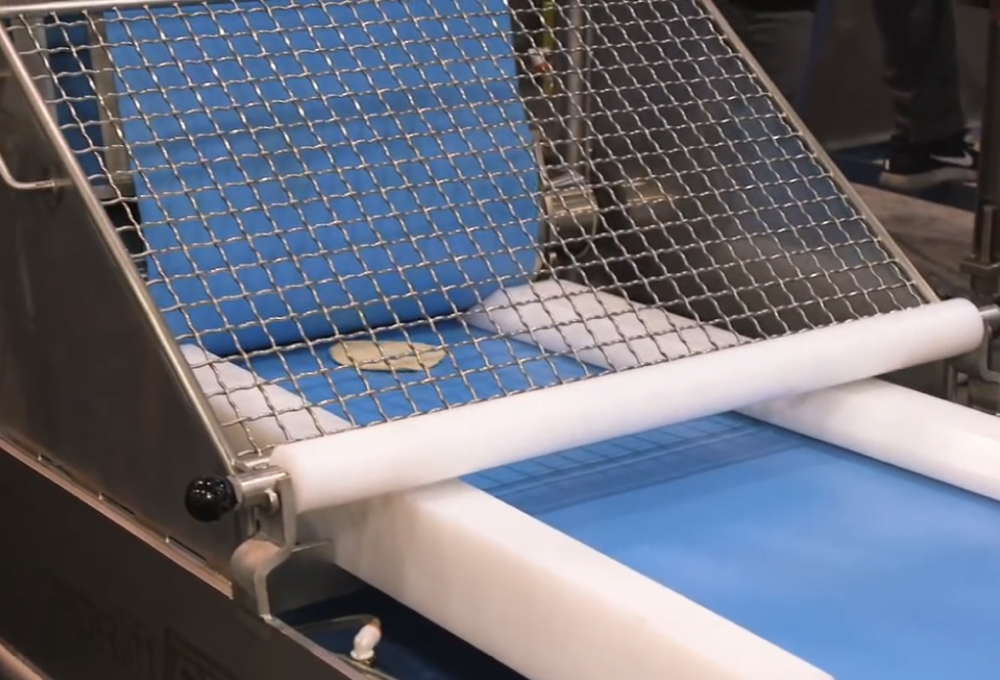

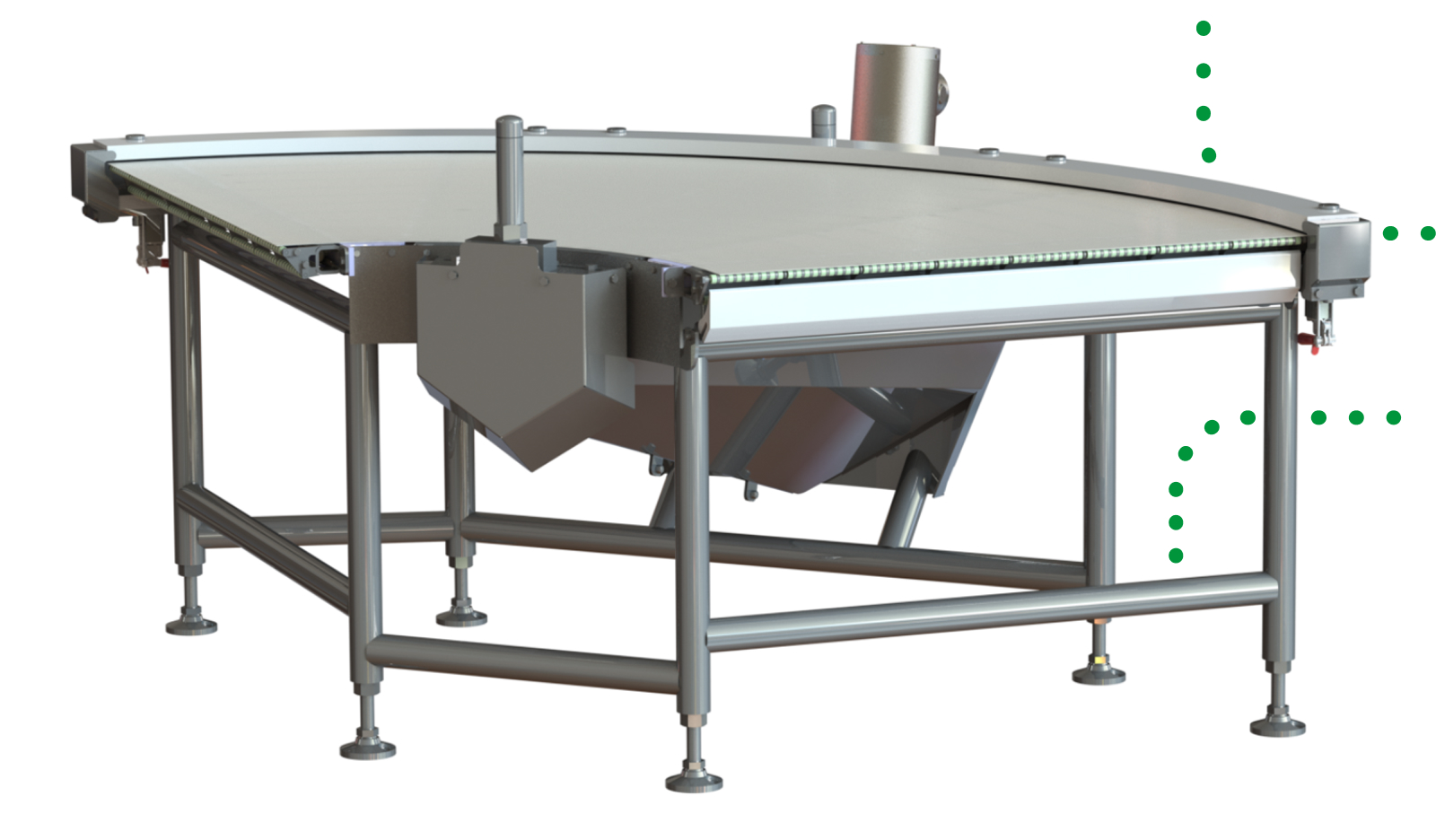

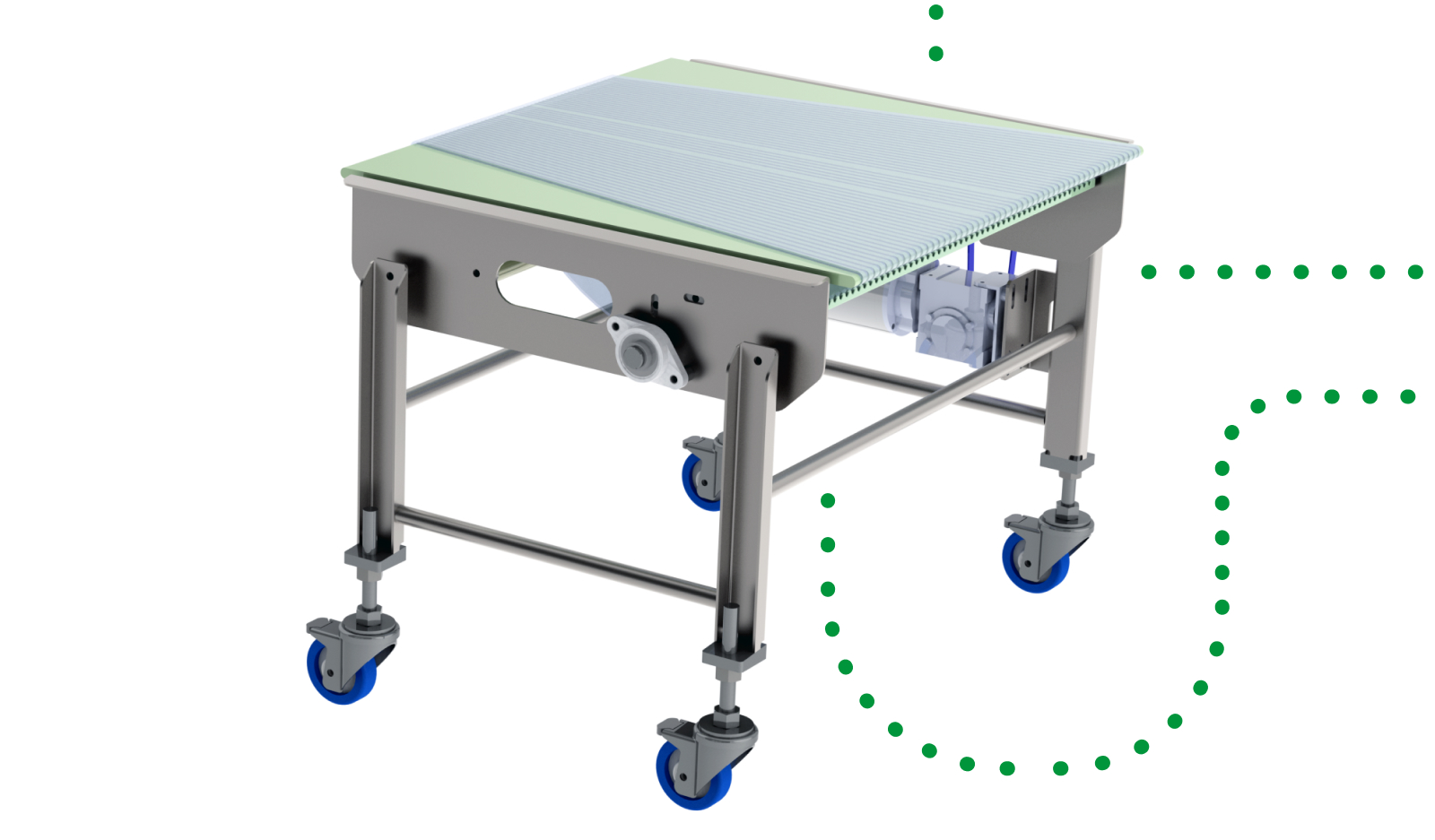

FLEXIBLE, MODULAR OPERATION

Spread, diverge, or converge product to the custom widths you need. Quickly and easily move on and off the line with caster footing.

-

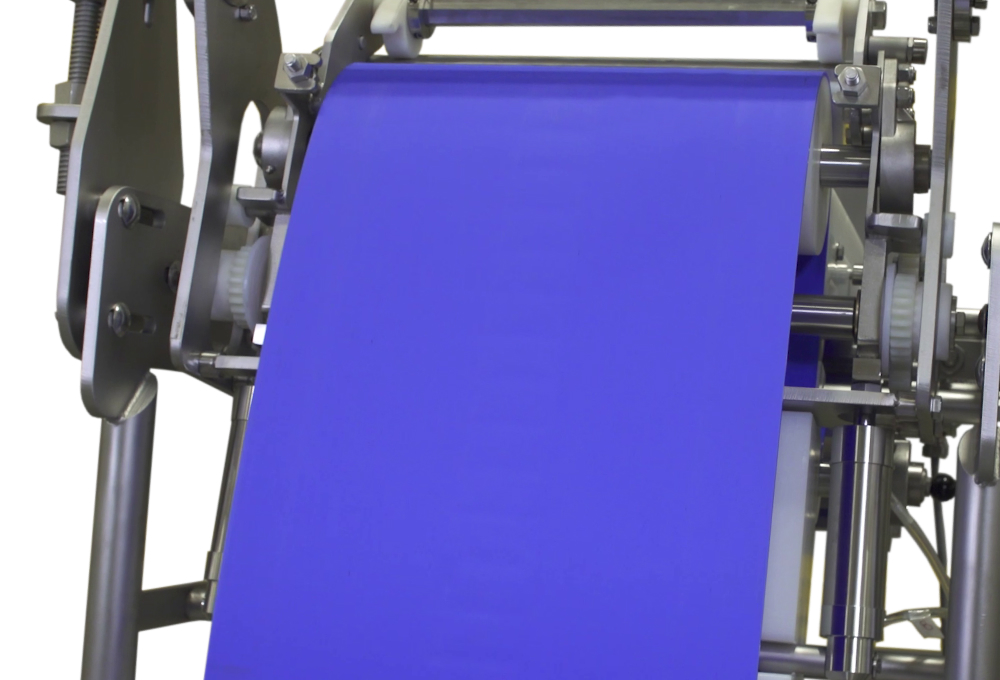

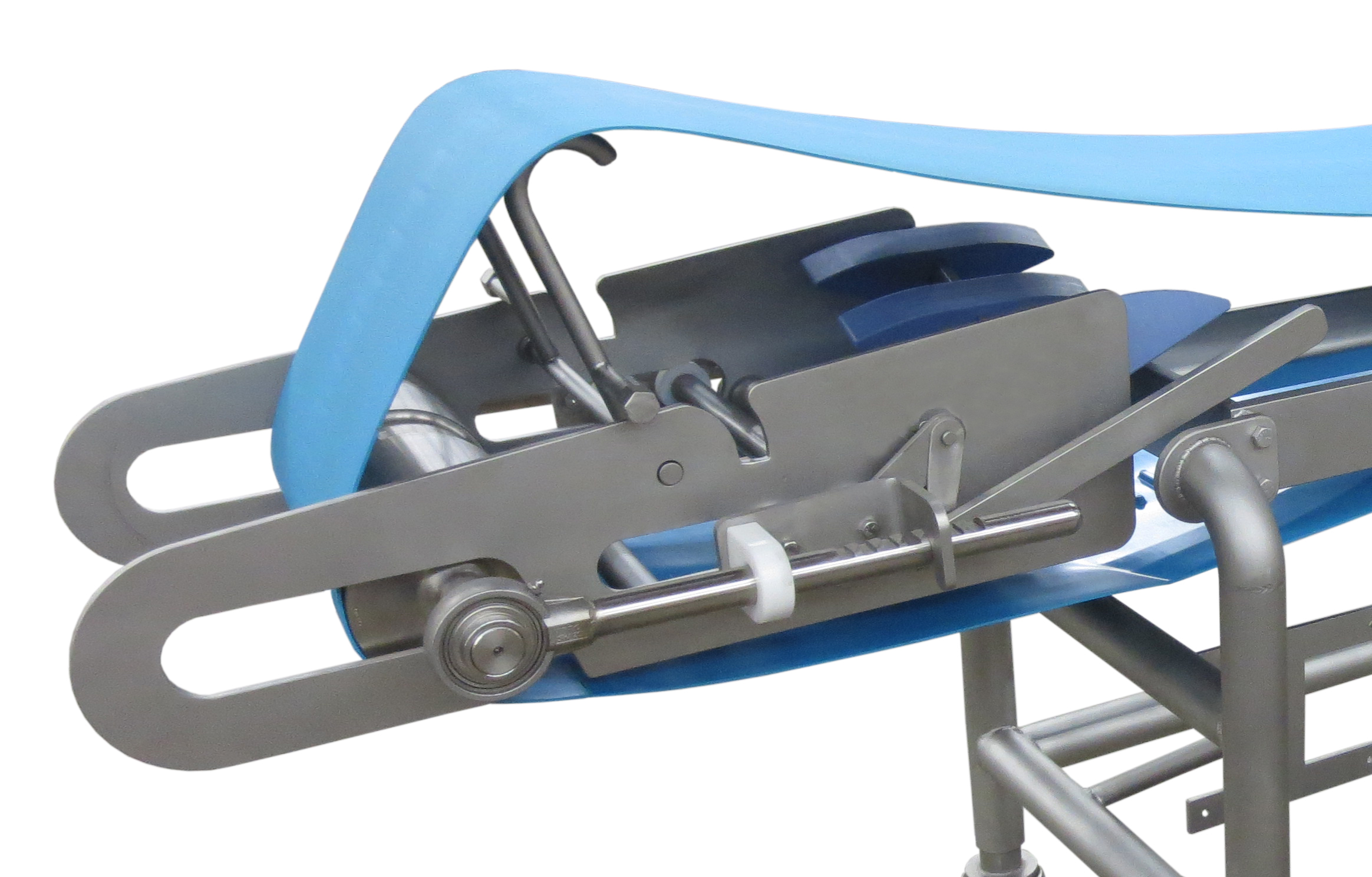

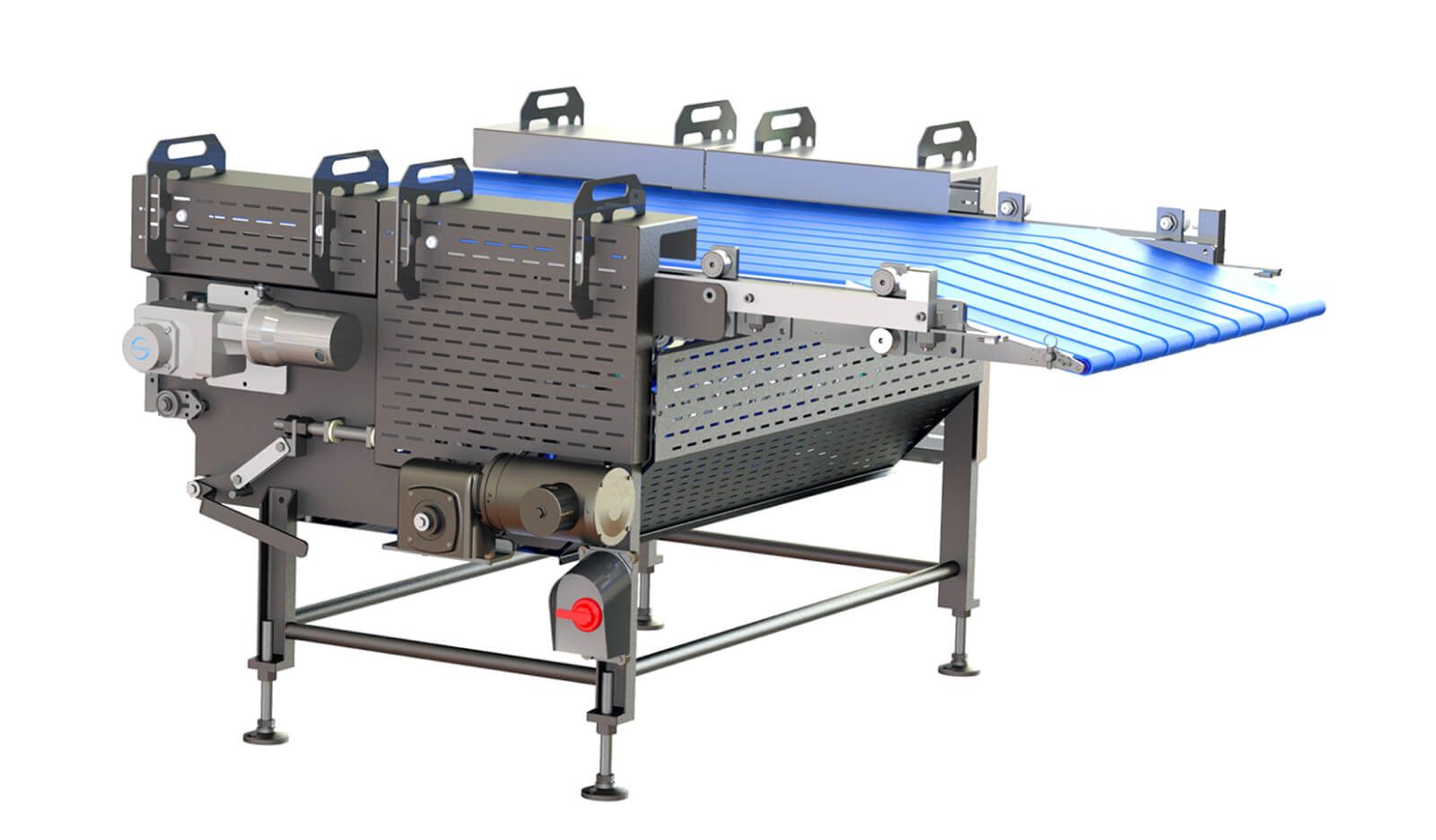

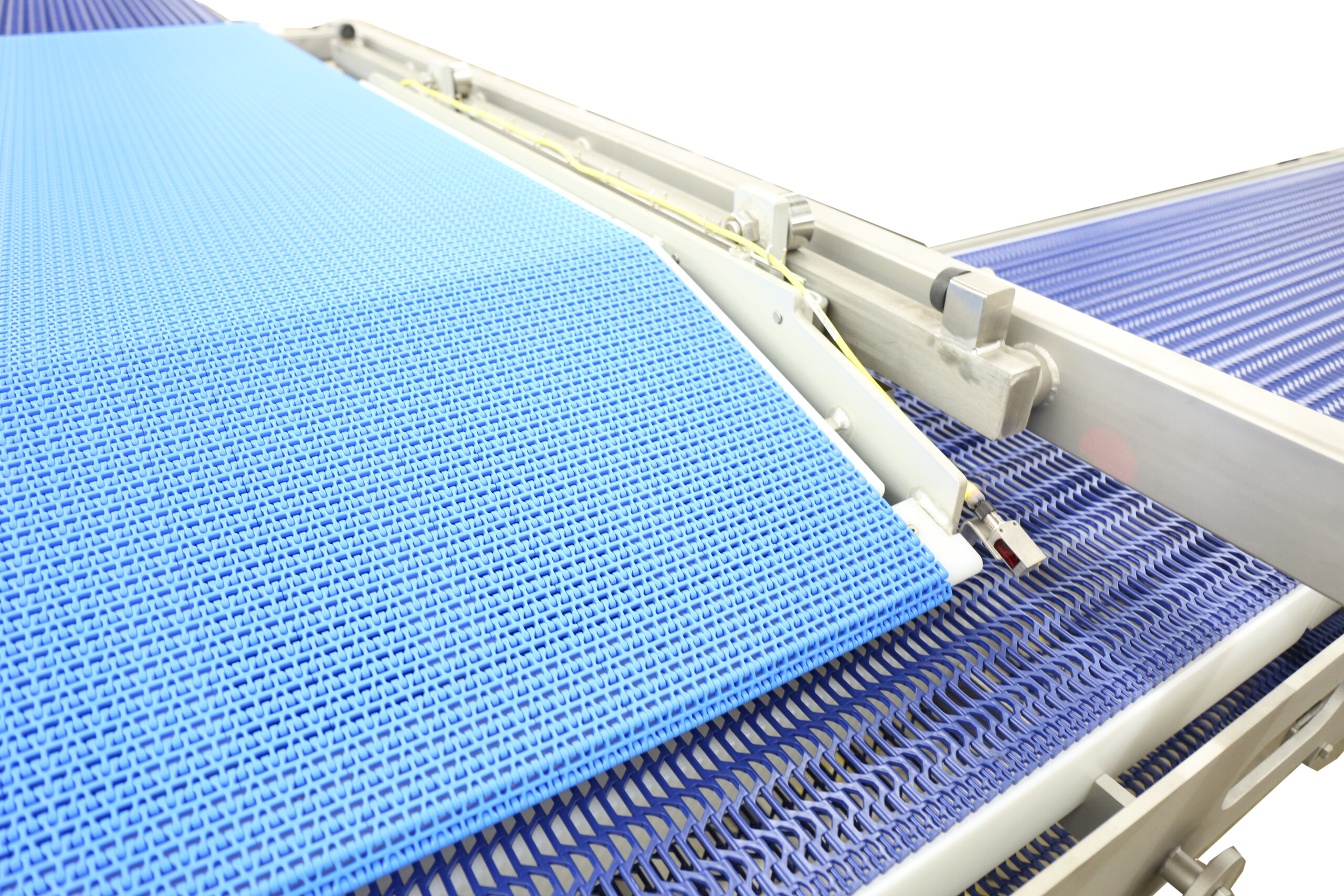

OPTIMAL PRODUCT HANDLING

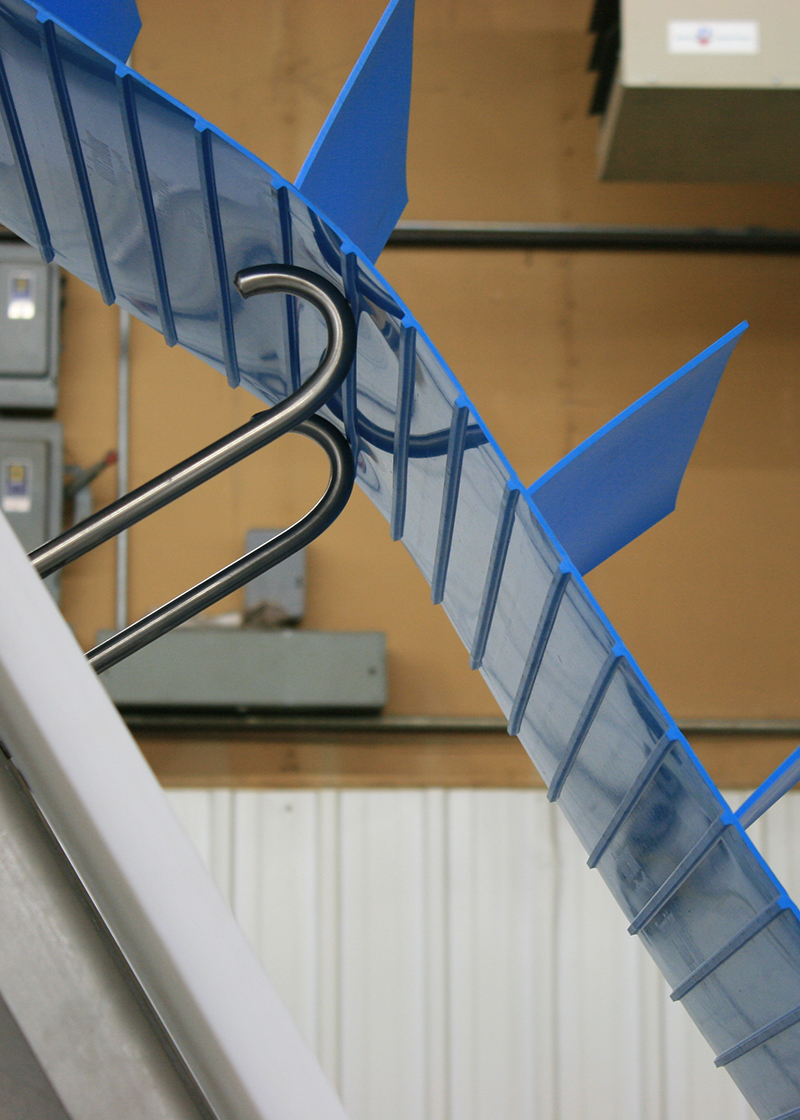

Positive drive non-slip flex chains ensure gentle handling, tight transfers, and perfect positioning for coating, or unpackaged and packaged products.

-

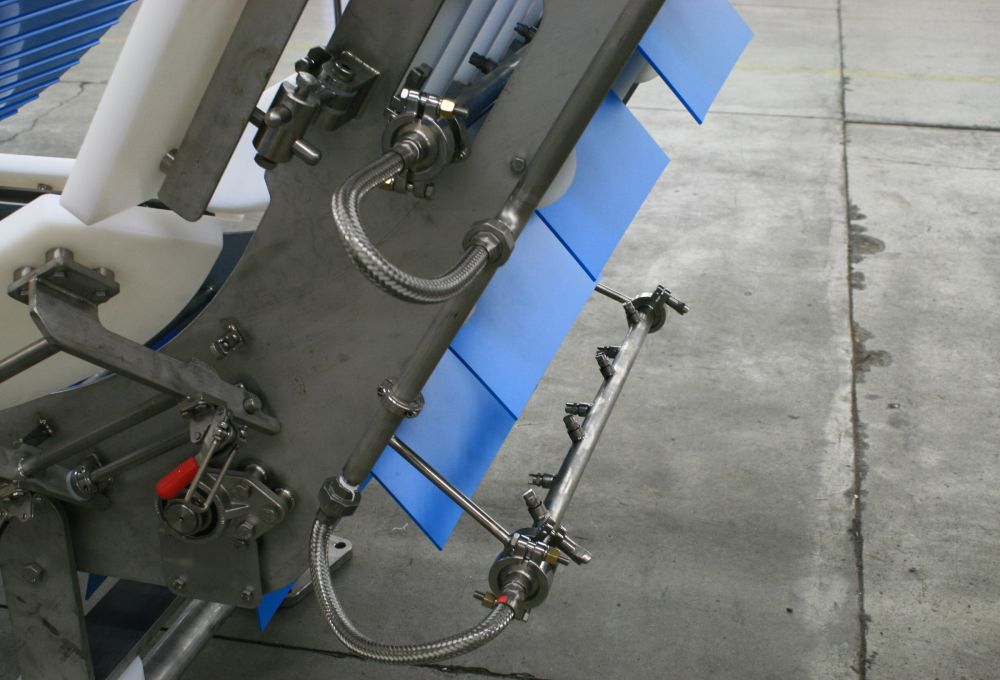

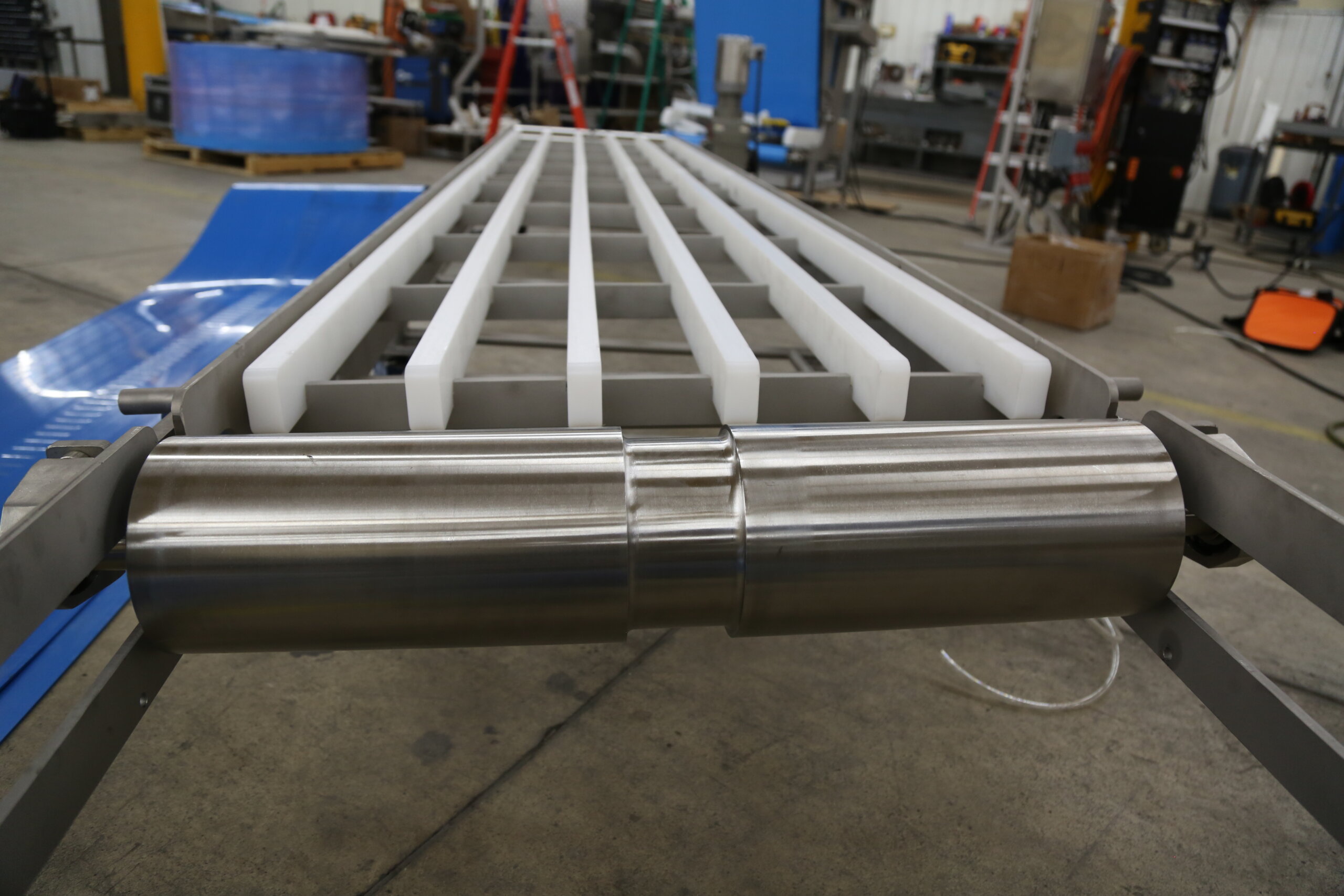

SANITARY & MAINTENANCE FRIENDLY

Featuring a positive drive system, stainless steel wire chains, and food-grade support surface for quick washdown.

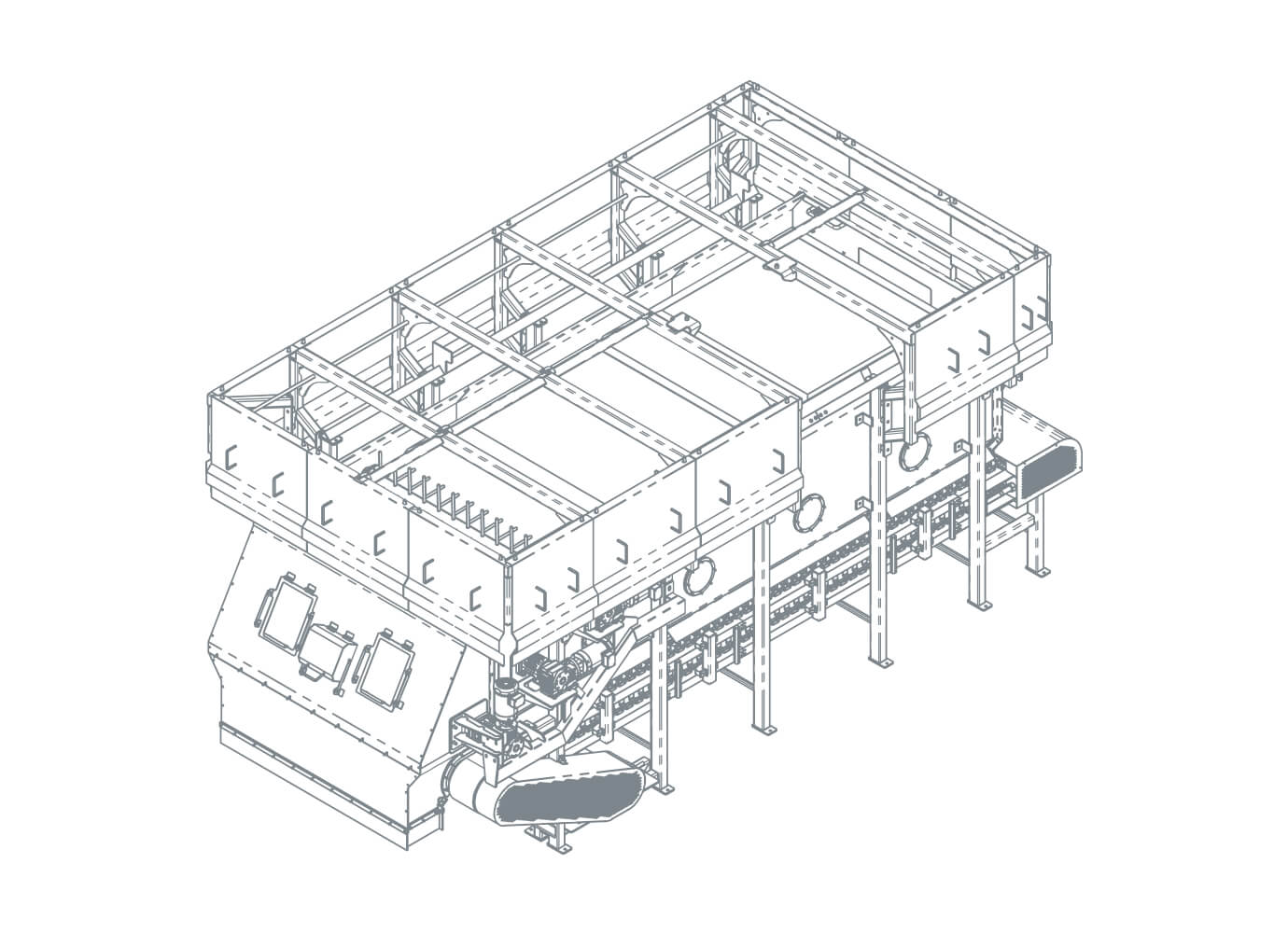

Product Features

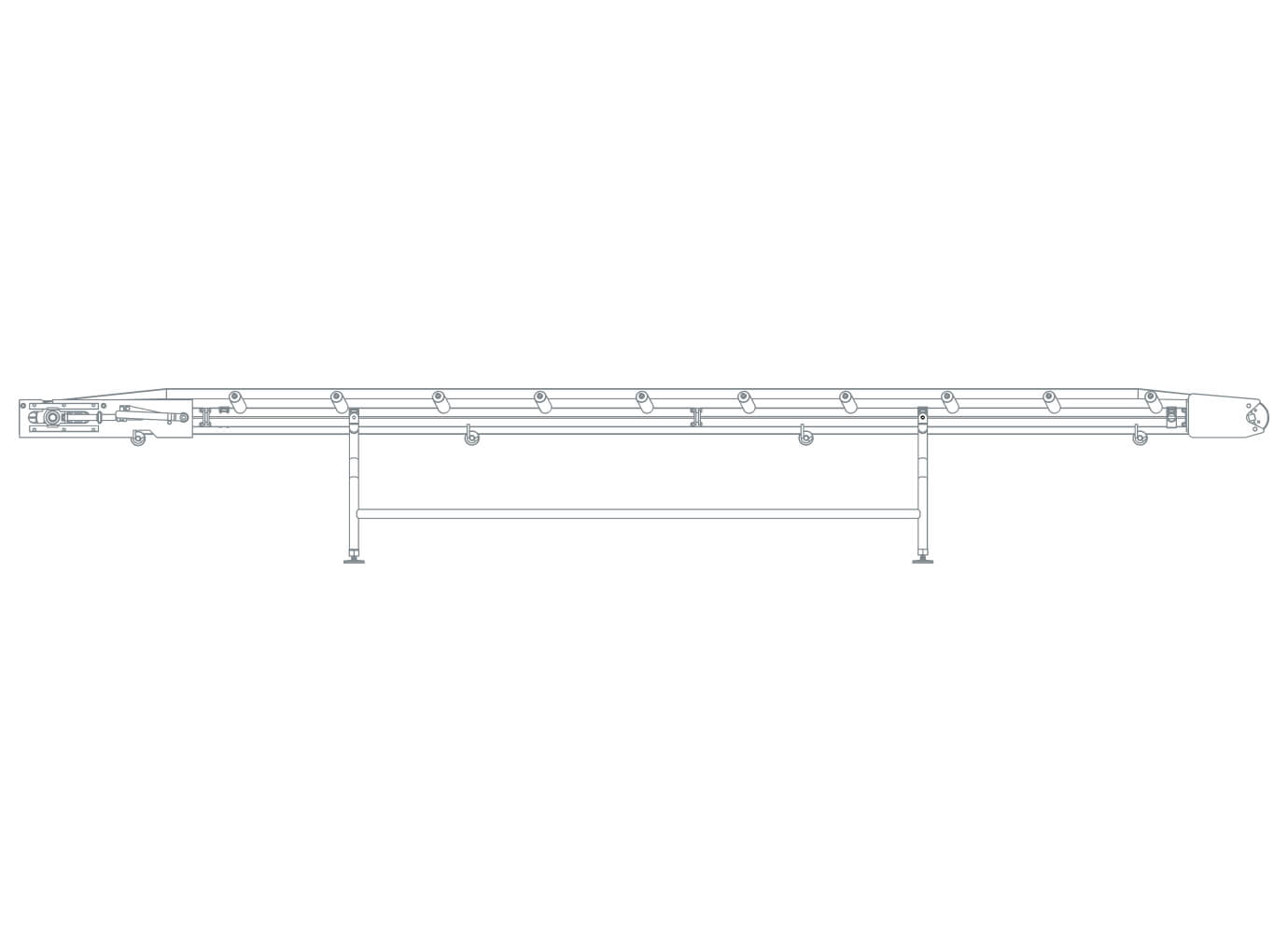

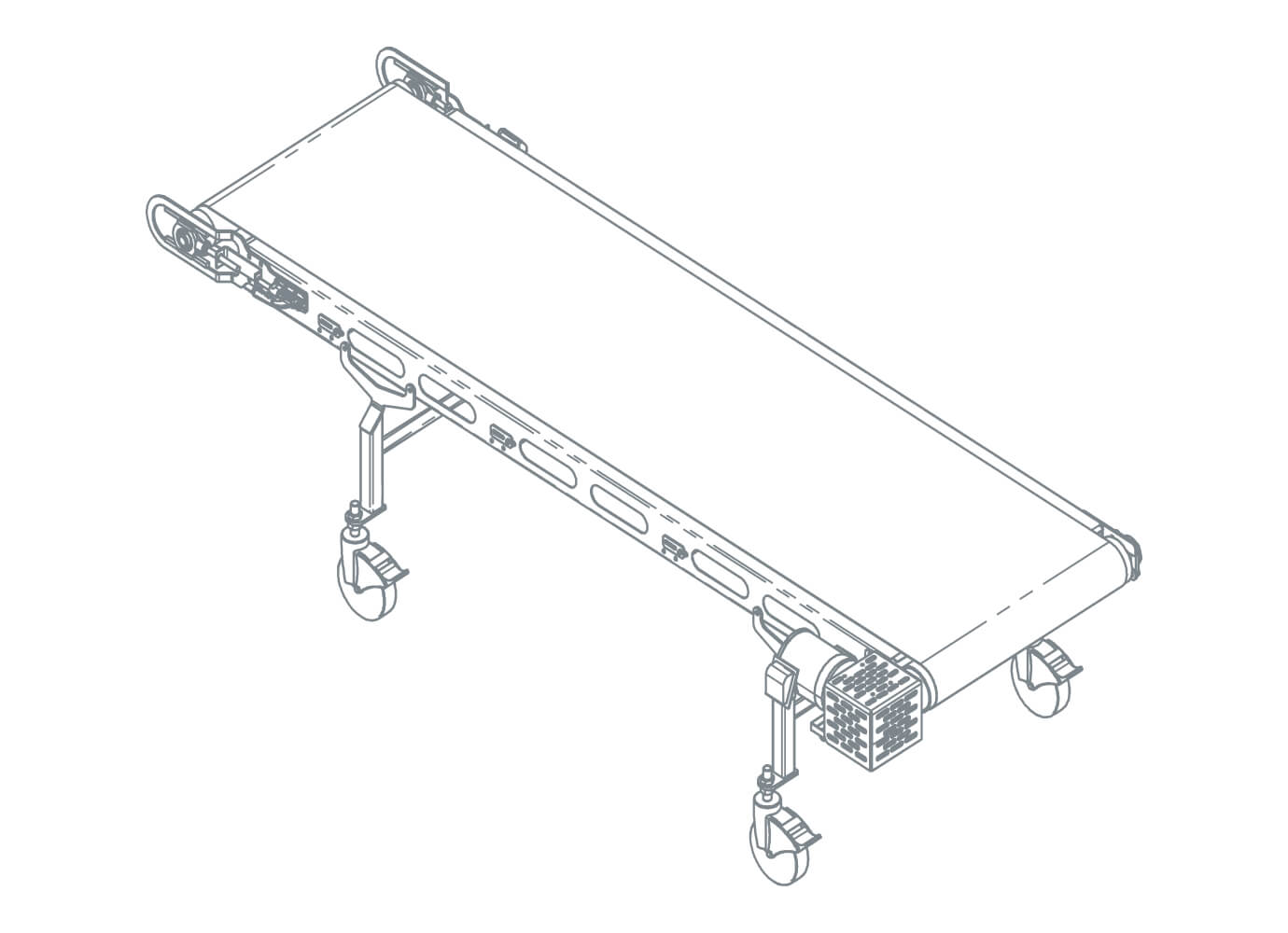

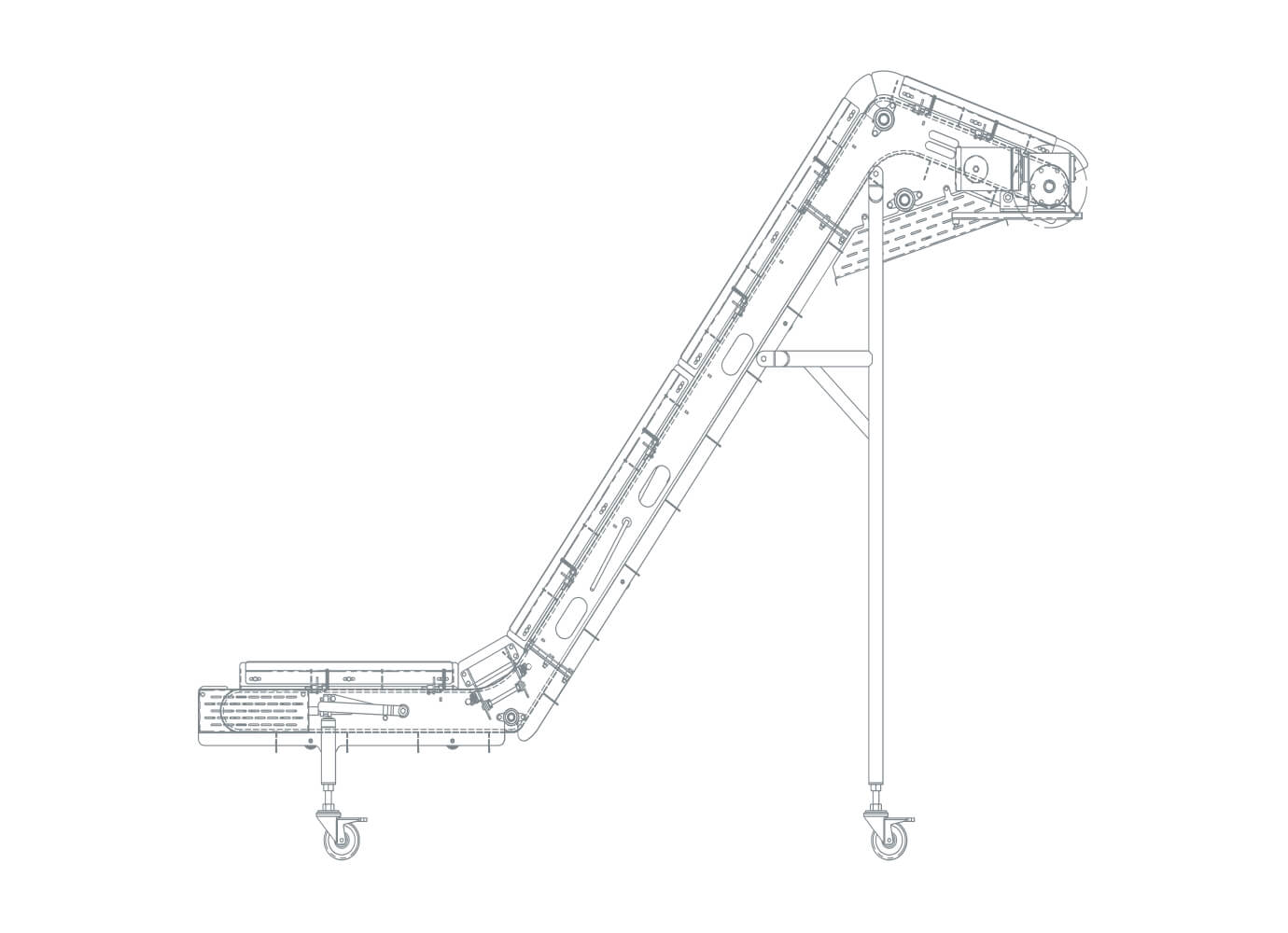

The Spreader links the key processes of your line by spreading, diverging, or converging product between wider and more narrow belts. Its positive drive, non-slip stainless steel flex wire chains position product seamlessly, with no jams or pile ups. Tight infeed and outfeed transfers ensure product orientation and integrity. The Spreader is designed for easy sanitation and maintenance.

-

Converge, diverge, and spread product between processes

-

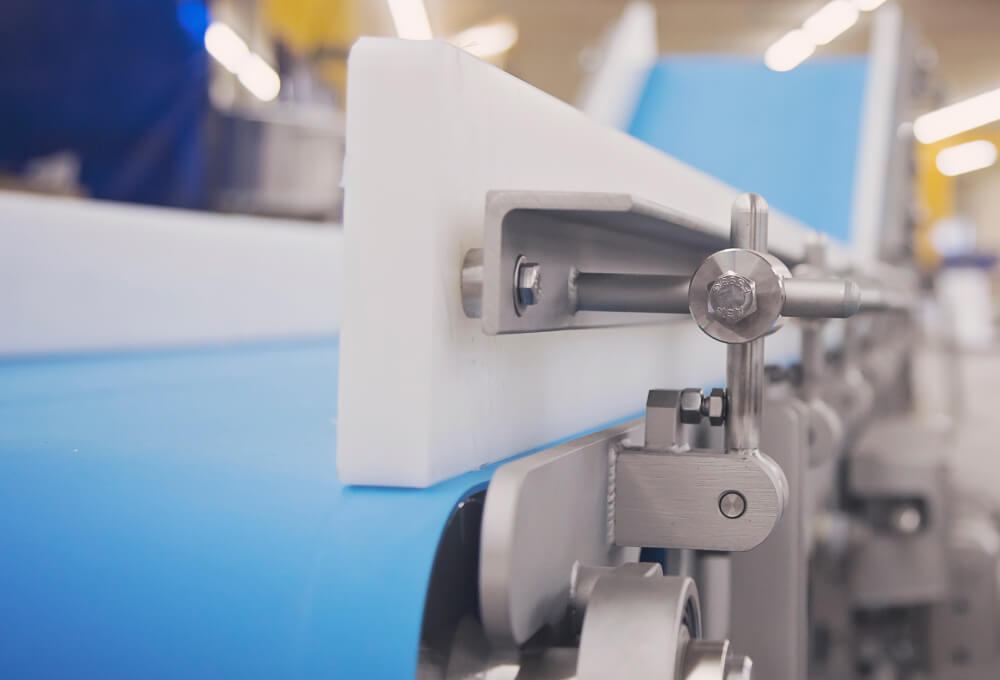

Positive drive, non-slip flex chains

-

Customize infeed and outfeed widths

-

Tight transfers for accurate orientation and gentle handling

-

Food-grade sanitary design with positive drive system, stainless steel construction

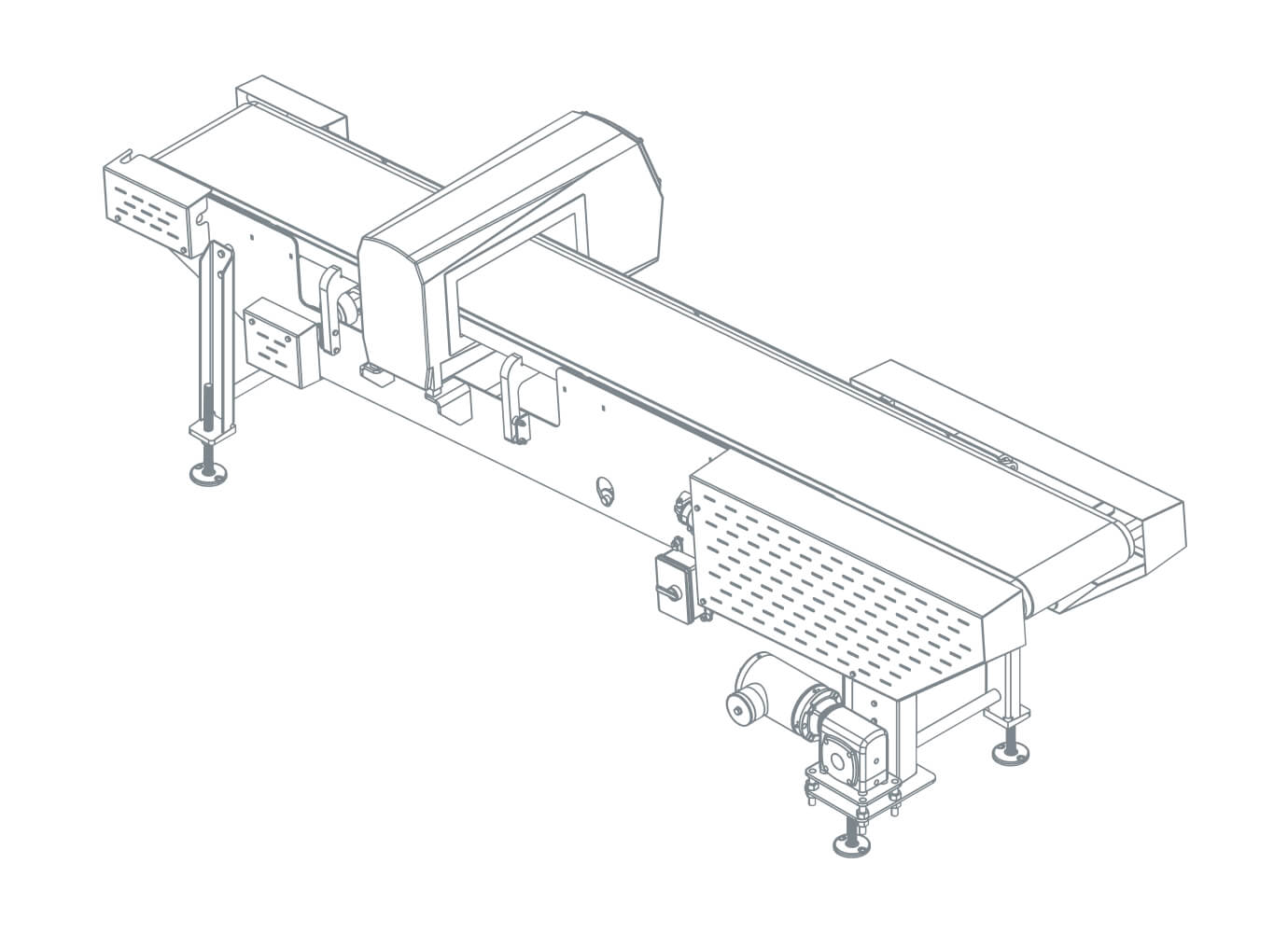

Equipment Information

Specs

Key details to help you decide if the Spreader is right for your operation

Positive drive

Stainless steel

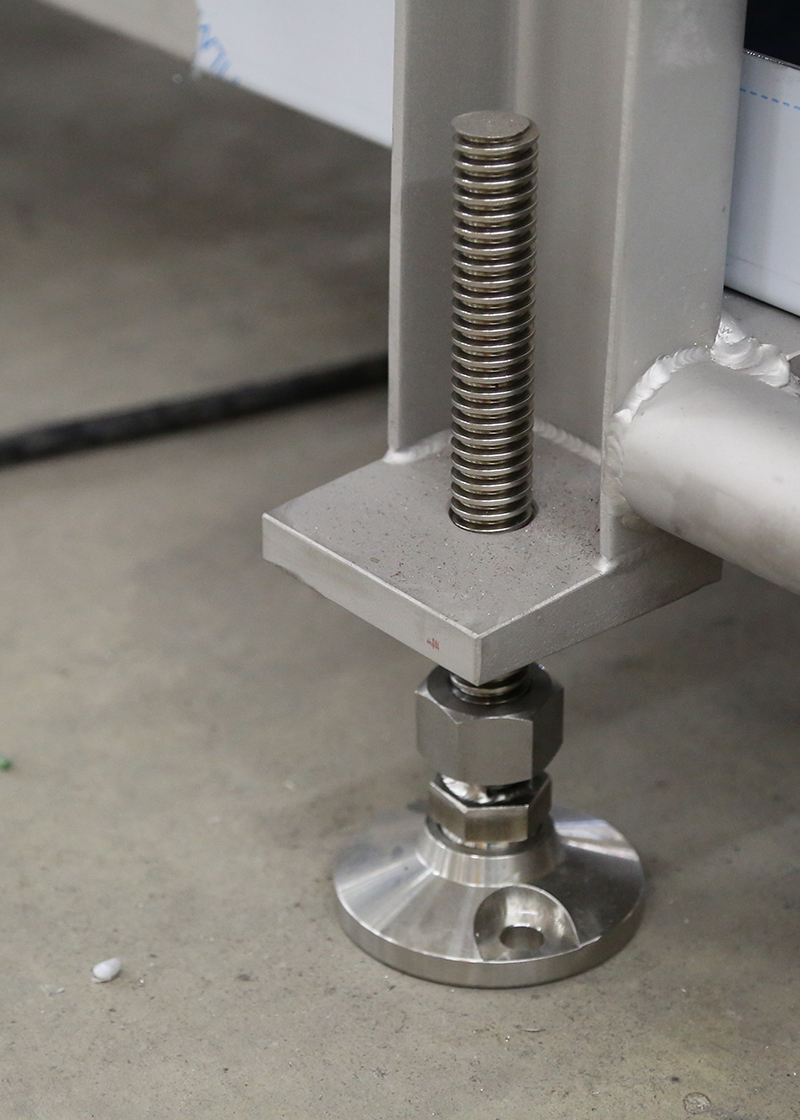

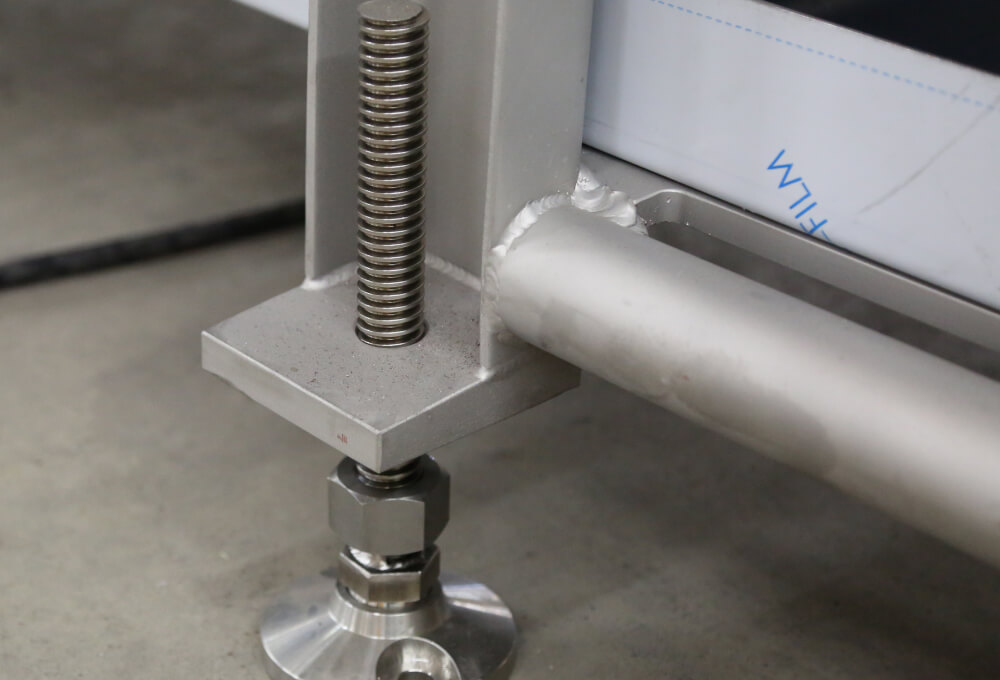

Locking caster feet

Chains

stainless steel flex wire, plastic modular

Options

Additional equipment options to customize the Spreader precisely to your application.

- Adjustable infeed and discharge widths

Service & Parts

Our expert project managers and technical service teams work hand-in-hand with you to find the solutions you need, quickly and efficiently, so you can stay up and running.

- Installation with onsite cutting and welding to get your operation up and running fast

- Electrical capabilities to integrate the entire line

- Training programs give your operators the know-how to keep it running

- Contact technical service via phone, email, and emergency support available 24/7

- Get equipment tuning, belting repair and replacement handled by experienced technicians right at your facility

COMMON FOOD INDUSTRIES

Whether your product is sticky, dusty, wrapped or not, the Spreader can transfer it throughout your processing line damage-free. Don’t see your products? We have decades of experience throughout the food industry – contact us for your custom configuration.

SANITARY DESIGN

We put sanitation and food safety at the forefront of our designs. The Spreader is designed for maximum accessibility and ease of cleaning, in line with food processing equipment standards.

RELATED EQUIPMENT

REQUEST A CONFIGURATION