Blog

Common Vibratory Conveyor Applications

Vibratory conveyors are essential tools in the food processing industry. They use controlled vibrations to gently move products along the production line–and so much more.

Vibratory conveyors offer food processing applications beyond basic transportation. This adaptability allows for customization with various pans, accommodating different products and uses. These value-added features make vibratory conveyors valuable tools for optimizing multiple processes, boosting productivity, and maintaining stringent quality standards.

Screening

One key value-added application of vibratory conveyors is screening. Utilizing a perforated pan, these conveyors efficiently remove unwanted materials such as small or broken pieces, fines, and other debris that can impact product quality.

The vibrations cause these unwanted particles to fall through the perforations, leaving behind a consistent, high-quality end product. This automated process improves the final product and reduces the need for manual sorting, leading to significant cost savings and improved overall efficiency in the production line.

Dewatering/Shaking

Vibratory conveyors (shakers) effectively remove excess water from wet products. As the product moves across a perforated screen, the vibrations drain water. This is especially useful for fruits and vegetables after washing, preparing them for packaging or further processing. This drying process prevents spoilage, maintains quality, and reduces contamination risk. It also improves efficiency in the following steps.

Laning

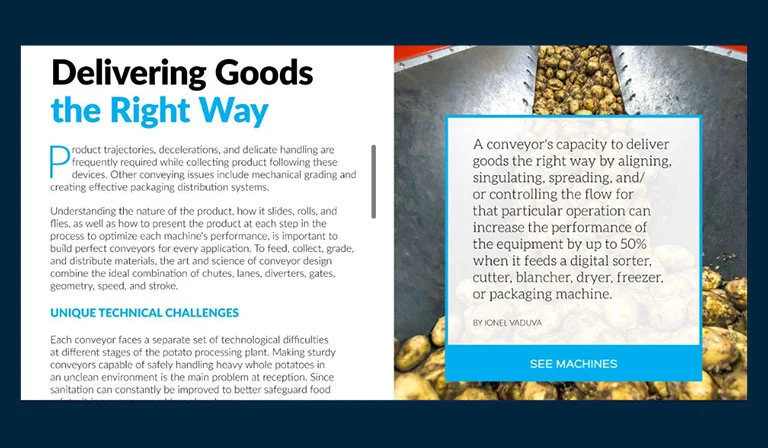

Aligning and orienting products is crucial for packaging or further processing in food operations. Vibratory conveyors with lanes guide products into specific positions, ensuring correct alignment for downstream operations. This setup increases efficiency and reduces the risk of misaligned products, jams, and damage. As a result, throughput improves, and waste decreases.

![]()

Sorting/Grading

Vibratory conveyors with adjustable screens or specialized sorting mechanisms can automate the sorting and grading process.

As products move across a series of perforated pans with different-sized holes, the vibrations cause them to fall through the appropriate holes, separating them based on size. This automated process ensures accurate and consistent product grading. It reduces the need for manual labor and minimizes the risk of human error.

![]()

Spreading

Maintaining a uniform distribution of products is crucial for many food processing operations, such as drying, coating, or inspection. Vibratory conveyors can be designed with spreading mechanisms that ensure an even layer of product across the entire width of the conveyor belt. This consistent flow improves throughput and reduces waste. It provides uniform processing, leading to better product quality and consistency.

Feeding

Vibratory conveyors are also used to control the product flow from bulk handling systems into downstream processes. The controlled vibration ensures a steady and consistent feed, preventing overfeeding or underfeeding that could disrupt production.

Mixing & Blending

One application of vibratory feeders is mixing and blending. Precise metering of ingredients is essential for maintaining accurate recipe formulations and consistent product quality.

![]()

WHY VIBRATORY CONVEYORS ARE THE IDEAL SOLUTION

Vibratory conveyors offer high throughput and rapid movement of large product volumes, which increases production levels. Their low maintenance requirements also make them ideal for minimizing downtime and reducing the total cost of ownership.

Vibratory conveyors are particularly well-suited for additional food processing applications due to several factors.

Increased Performance Without Additional Equipment

Customizable pans on vibratory conveyors and feeders can perform various applications, eliminating the need for multiple machines. This value-added approach allows for the simultaneous conveyance and manipulation of products while improving overall efficiency. Food processors enjoy reduced capital budget, line footprint, and operations and maintenance.

Sanitation & Food Safety

![]() Maintaining hygiene and product integrity is paramount in food processing. Their sanitary design meets these stringent requirements. One-piece, smooth pans with angled side edges eliminate areas where a product can build up or become contaminated.

Maintaining hygiene and product integrity is paramount in food processing. Their sanitary design meets these stringent requirements. One-piece, smooth pans with angled side edges eliminate areas where a product can build up or become contaminated.

Vibratory conveyors are designed with sanitation in mind. Compared to belt conveyors, the minimal number of moving parts reduces potential contamination points. Their open-access frames also allow for quick and easy cleaning, maintenance, and swab testing. This ensures that production can resume promptly after these procedures.

Gentle Handling Equals Optimal Product Integrity

The gentle vibration of these conveyors helps maintain product integrity. The precise vibration frequency is carefully calibrated to move products without causing damage (e.g., breakage or seasoning loss). This gentle handling is crucial for preserving the quality and appearance of delicate or fragile products.

The continuous movement prevents slippery products like meat from remaining stationary for extended periods. This helps avoid unsafe temperature zones caused by friction or production stoppages.

SEAMLESS INTEGRATION INTO FOOD PROCESSING LINES

Due to their adaptable design, integrating vibratory conveyors into existing food processing lines is straightforward. Depending on the specific application, they can be easily installed at various points in the line.

Whether transporting ingredients between processing stages, sorting products by size, or dewatering washed vegetables, vibratory conveyors can be customized to fit the unique needs of each operation. They can handle a wide range of food products, from dry snacks and pet food to soft bakery items and meats, making them a valuable asset for any food processing facility.

PFI: YOUR PARTNER IN VIBRATORY CONVEYOR SOLUTIONS

PFI is your trusted expert in vibratory conveying solutions for the food processing industry. We design and build custom sanitary systems that gently handle your products, clean easily, and offer long-lasting value. Popular models include the versatile VFII, the precise EDF feeder, and the efficient MAGNEflex.

Food safety is our top priority. We use stainless steel and minimal moving parts, reducing maintenance needs and improving hygiene. Our systems ensure optimal product handling to minimize product damage regardless of the food type. We offer flexible configurations and work closely with customers to integrate our equipment into existing processes.

PFI boasts decades of experience and a commitment to quality. We will help you find the perfect vibratory solution to optimize your production line and achieve energy efficiency. Our expertise and commitment to quality ensure a reliable and efficient system that enhances your production.

Click below to explore how our vibratory conveyor solutions can enhance your food processing line.

Quicklinks

© 2024 PFI. ALL RIGHTS RESERVED. | Privacy Policy | Terms and Conditions