Food processing plants face mounting pressure to increase production while maintaining strict safety standards. Equipment that worked fine years ago now creates daily obstacles and rising maintenance costs. Running an outdated conveyor system puts product quality, food and worker safety, and company growth at serious risk.

Modern conveyor technology offers solutions to these growing challenges. New designs boost production efficiency while simplifying cleaning and maintenance. Read on to learn when to upgrade a food conveyor system.

THE SIGNS OF A FAILING CONVEYOR SYSTEM

Food manufacturers often overlook warnings that their conveyor systems need replacement until major problems emerge. Knowing the main signs of equipment issues enables plant managers to fix problems early. This proactive approach prevents expensive crises from compromising production, food quality, employee safety, and profitability.

1. Frequent Breakdowns & Costly Downtime

Recurring equipment failures do more than just interrupt production – they drain maintenance budgets and strain technical resources. When repair costs start approaching the price of new equipment, especially with rising expenses for obsolete parts, upgrading becomes the smarter financial choice.

Aging components fail more frequently, creating maintenance bottlenecks as technicians spend more time troubleshooting and replacing parts. The lost production often costs more in missed schedules and overtime labor than investing in new equipment would require.

2. Outdated Technology & Inefficiency

Outdated conveyors can slow down your entire production line. These older systems run at slower speeds than modern equipment and lack the smart features needed to adjust their pace based on upstream or downstream conditions.

Even basic efficiency features found in newer conveyors, such as automatic belt tensioning or self-adjusting guides, are absent from older models. This means workers must constantly make manual adjustments to keep products flowing smoothly. When these adjustments fail, products bunch up or spread too far apart, creating waste and reducing throughput.

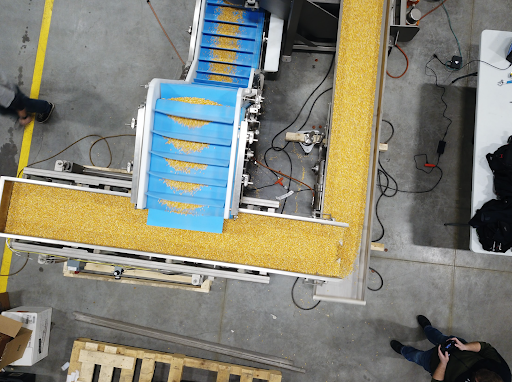

Fortunately, advancements in conveyor technology offer innovative solutions to these challenges. For example, replacing old belt conveyors with modern vibratory or horizontal motion systems can significantly improve efficiency and sanitation. These newer technologies are designed to handle a wider range of products and adapt to varying production demands with minimal manual intervention.

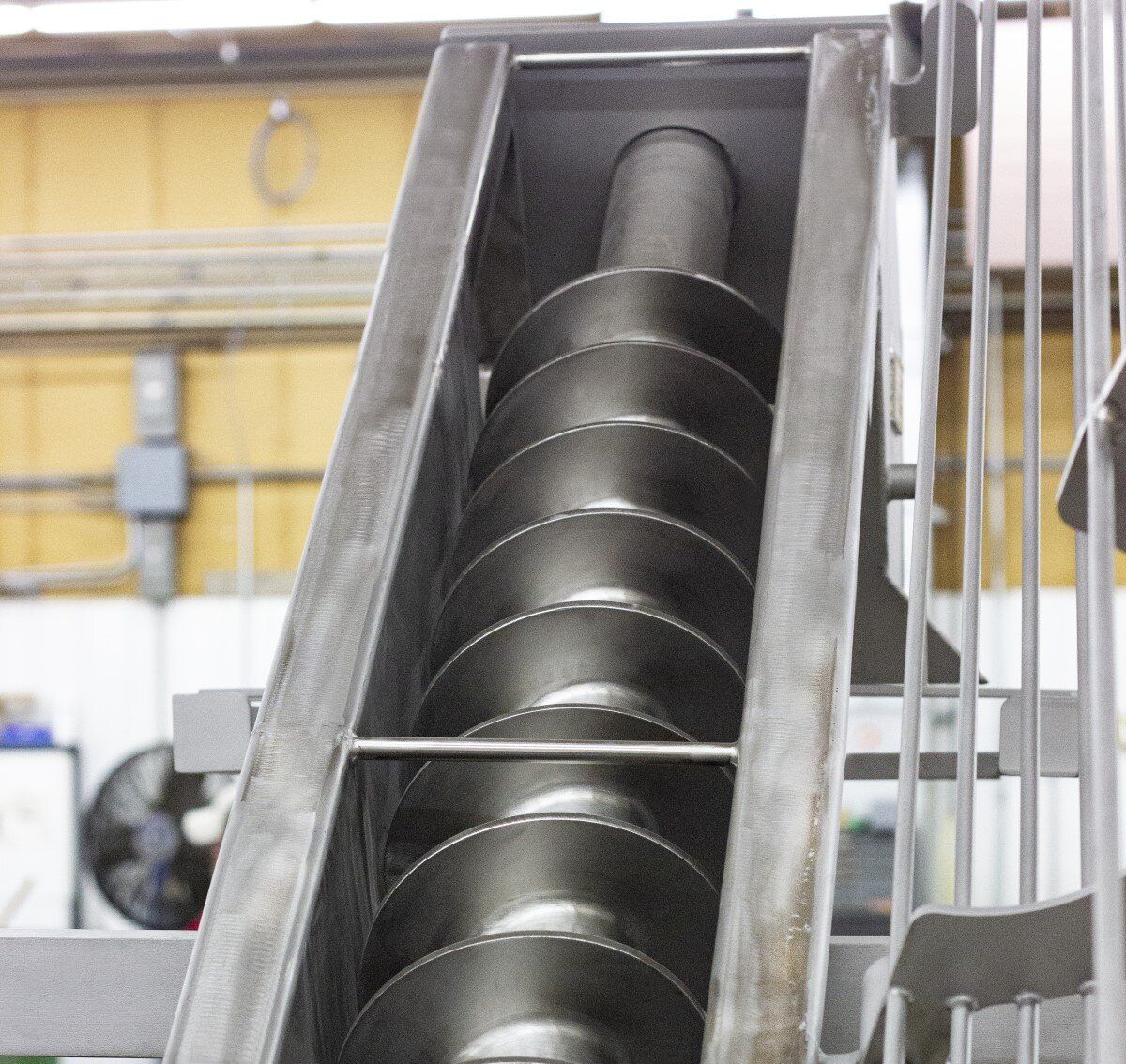

Additionally, creative repurposing of existing equipment can unlock new efficiencies. For instance, the PURlift, traditionally used for dough handling, can now be adapted for other applications with similar consistencies, such as raw meat or peanut butter. This flexibility not only extends the utility of your equipment but also reduces the need for costly new investments.

3. Noncompliance

Older conveyor systems present multiple risks that can damage your operations, reputation, and bottom line. Today’s food safety and worker protection standards demand equipment designs that older ones simply weren’t built to deliver. Here’s how outdated conveyors put your operation at risk:

Food Safety & Compliance Issues

Old conveyors are not designed to today’s sanitation and food safety standards. They may be manufactured in mild steel and have inaccessible areas and many moving parts that are difficult to clean and sanitize properly. This allows harmful bacteria to grow and contaminate food products. These contamination risks can trigger costly recalls and harm your brand reputation. Beyond recalls, failing to meet HACCP and GMP regulations can result in steep fines, legal challenges, and potential facility closures.

Worker Safety & Operational Limitations

Outdated conveyors lack essential safety features such as guards and emergency stops, exposing workers to serious injury risks. These older systems also struggle to handle modern production demands, forcing workers to spend more time on manual adjustments and increasing the likelihood of accidents.

Upgrading your food conveyor system with advanced safety features protects employees, improves productivity, and increases operational efficiency.

Why Modern Standards Matter

The shift from mild and painted steel to stainless steel construction marks a crucial advancement in food safety. Modern stainless designs resist corrosion and prevent bacterial growth, while open frames allow thorough cleaning and inspection. Current sanitary standards now cover entire processing lines, not just specific zones.

New conveyor technologies, like horizontal motion and vibratory systems, offer better sanitation through inherent design features. These improvements make compliance easier and protect both workers and consumers.

4. Changes in Production Requirements

Older conveyor equipment can’t handle the challenges of increased production. Sales growth and expanding product lines reveal severe limitations in this outdated machinery. Modern manufacturing demands quick changes between products and higher output rates. These aging conveyors fail to deliver on both counts.

The daily struggles impact every part of production. Orders pile up because conveyors run at fixed, outdated speeds. New product sizes require flexible equipment adjustments. Plant managers face tough choices between maintaining quotas or investing in new equipment that meets their current (and future) needs.

5. Increasing Maintenance Expenses

Aging conveyors steadily drain maintenance budgets beyond reasonable costs. Each month brings new repair expenses while replacement parts become harder to source.

Basic components like bearings and belts now fail at an alarming rate on older systems. Many manufacturers no longer make parts for outdated models, so prices keep rising for the few remaining parts.

The maintenance team logs extra hours every week to handle frequent breakdowns. Emergency repairs pile up extra costs through overnight parts shipping and overtime pay. What started as routine upkeep has evolved into a constant financial strain on operations.

THE RISKS OF USING AN OUTDATED CONVEYOR SYSTEM

Outdated conveyor systems pose serious food safety risks. Hard-to-clean designs harbor bacteria, leading to contamination and costly recalls. Sick consumers and damaged brand reputations often follow. Failing to meet food safety standards can also result in hefty fines, legal fees, and even facility shutdowns.

Worker safety is another critical concern. Missing safety guards and broken emergency stops increase the risk of injuries or fatalities. These incidents lead to worker compensation claims, lawsuits, and higher insurance premiums. A single accident can devastate a company’s reputation and financial stability.

Production limitations from outdated systems can cripple growth. Slow, inefficient conveyors cause delays, missed deadlines, and lost sales. Retail contracts may be canceled, and competitors with modern equipment will seize market share. Over time, these setbacks can force plants to close and businesses to shut down entirely.

BENEFITS OF MODERN SANITARY FOOD CONVEYOR SYSTEMS

Food manufacturers face intense pressure to increase output while maintaining strict safety standards. The latest conveyor technology transforms how plants meet these challenges with the following features and benefits:

Built-in Sanitation Features

Tool-free components make cleaning between production runs faster and easier. The open frame design eliminates hard-to-reach crevices, lowering the risk of contamination. Optional features like Clean In Place (CIP) systems and belt scrapers allow for cleaning during production, reducing downtime and keeping operations running smoothly.

Minimal Maintenance Needs

Advanced motion technology eliminates most worn parts found in traditional systems. Vibratory conveyors need only annual spring replacements. This reduction in maintenance needs keeps production running smoothly with fewer interruptions.

Precise Product Handling

Adjustable guide rails and controlled product movement work together to prevent waste and damage. Belt-cleaning attachments efficiently remove residue and stop potential issues before they arise.

Vibratory and horizontal motion systems deliver gentle handling, which is ideal for fragile or coated products. This ensures no loss of yield or breakage during processing. Horizontal motion systems also feature immediate stop/start functionality, maintaining optimal product flow.

Smart Control Systems

Automated controls now handle tasks that once required constant manual adjustments. Sensors throughout the line communicate to maintain consistent product flow. This intelligent monitoring prevents bottlenecks while reducing operators’ workloads.

Easy System Adaptation

Modern conveyor systems offer unmatched flexibility to scale production up or down as needed. Vibratory pans, for example, can be customized for tasks ranging from basic transport to precise sizing or laning.

These systems can be adapted to fit any production environment and perform various functions. Plants can expand capacity by adding matching units or upgrading to faster equipment, ensuring seamless growth and adaptability.

CUSTOMER SUCCESS STORY: BAKERY DOUGH RESIDUE SOLUTION

A major bakery faced rising sanitation costs from sticky dough residue on its conveyor lines. Raw dough stuck to belts, and transfer points created contamination risks. The cleanup process required four hours of intensive scrubbing each day.

PFI engineers designed a custom solution with a sanitary dough coffin and incline belt system. The new design featured a tool-less belt scraper for quick cleaning access. Special non-stick surfaces prevented dough from adhering to critical transfer points.

The results transformed the bakery’s production schedule. Daily cleaning time dropped from four hours to less than two. The maintenance team eliminated emergency contamination cleanups. Production uptime increased while sanitation costs decreased.

This success story highlights why modern conveyor design matters. The right equipment turns common industry problems into opportunities for improvement. Features like tool-less cleaning access and non-stick surfaces deliver measurable benefits in safety, efficiency, and cost reduction.

PREPARING FOR THE FUTURE & PARTNERING FOR SUCCESS

Smart planning for equipment upgrades requires a clear view of industry trends. Food safety standards grow stricter each year while production demands increase. Consumer preferences change rapidly, forcing manufacturers to adapt quickly. Meanwhile, automation and data analytics reshape how plants operate and compete.

Proactive Food Safety & Sanitation

Current and upcoming regulations will demand higher sanitation standards from food manufacturers. New conveyor designs anticipate these changes with surfaces that resist bacterial growth. Quick-release components and tool-less cleaning access help plants maintain the strictest hygiene protocols.

Adaptable & Flexible Operations

PFI excels at customizing solutions to ensure seamless integration with minimal disruption. Our rapid lead times enable businesses to adapt to new product demands swiftly. By leveraging our expertise, you can enhance productivity and maintain competitiveness in today’s fast-paced market.

Scalable Automation & Data-Driven Insights

Smart sensors now track every aspect of conveyor performance. Built-in automation controls adjust settings to maintain peak efficiency. This continuous data stream helps plants spot trends and prevent problems before they impact production.

Support and Expertise for Your Upgrade

The path to improved production starts with understanding your specific needs. Our consultative approach focuses on designing systems that match your application requirements, production rates, and available space. This careful planning creates solutions that serve your business today while adapting to tomorrow’s challenges.

Professional installation ensures optimal conveyor performance from day one. PFI’s installation team handles every aspect of setup and testing for reliable long-term operation. Expert technicians verify all components meet specifications while training your staff on proper operation and maintenance procedures.

Sourcing equipment and support from the same supplier streamlines quoting, accounting, and communication. Our teams’ deep knowledge of our equipment increases the success of your upgrade.

GAIN A COMPETITIVE EDGE WITH MODERN CONVEYOR SOLUTIONS

Investing in modern conveyor equipment protects food safety while boosting production efficiency. Equipment upgrades provide the foundation for sustainable business growth in today’s competitive market. Smart planning for these improvements helps manufacturers stay ahead of changing industry demands.

PFI leads the food manufacturing industry with innovative conveyor solutions backed by decades of expertise. Our engineering team works closely with clients to design systems that exceed safety standards and performance goals. Click below to explore our complete line of sanitary food conveyor solutions.

Explore Our Food Conveyors